LCD-Anzeigen sind weit verbreitet in verschiedenen Branchen und Verbraucheranwendungen. Um ihre Leistung und visuelle Klarheit in verschiedenen Umgebungen zu verbessern, wenden Hersteller häufig spezifische Oberflächenbehandlungen an. Anti-Blendung, Anti-Reflexion und Anti-Fingerabdruck sind drei gängige Oberflächenbehandlungen des LCD, um visuelle Störungen zu reduzieren und bessere visuelle Effekte zu erzielen. Diese Behandlungen verbessern nicht nur die Lesbarkeit, sondern erweitern auch die Benutzerfreundlichkeit von Displays unter anspruchsvollen Licht- oder Gebrauchsbedingungen.

Verständnis der Glasoberflächenbehandlungen: AG, AR, AF

Jede Art der Oberflächenbehandlung bietet einzigartige Vorteile basierend auf ihren physikalischen Eigenschaften und dem beabsichtigten Gebrauch. AG-Beschichtung (Anti-Glare), AR-Beschichtung (Anti-Reflexion) und AF-Beschichtung (Anti-Fingerabdruck) dienen unterschiedlichen Funktionen, um das Benutzererlebnis mit LCD-Panels zu verbessern.

AG (Anti-Glare) Beschichtung

Was ist Anti-Glare Coating?

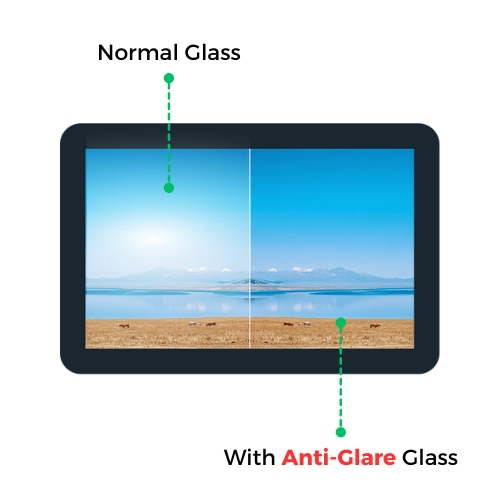

AG Beschichtung macht die reflektierende Oberfläche des LCD zu einer matten Oberfläche und ändert die Oberflächenrauheit durch das Verfahren des chemischen Ätzens oder der Sprühschicht, um einen matten Effekt zu erzielen.

Wie AG Coating Glanz reduziert und Licht verbreitet

Wenn das äußere Licht auf die Oberfläche reflektiert, tritt eine diffuse Reflexion auf, um die Reflexion des Lichts zu verringern. Dies bedeutet, dass die Benutzer anstatt scharfe Reflexionen oder Blendungen von Umgebungslichtquellen zu sehen, ein erweichtes Bild mit verbesserter Sichtbarkeit erleben.

Vorteile und Einschränkungen von AG Coating in LCDs

Der Hauptvorteil ist die verbesserte Lesbarkeit unter hellen Bedingungen, insbesondere im Freien. Allerdings können AG-Beschichtungen aufgrund ihres diffusen Charakters den Kontrast leicht reduzieren. Trotzdem bieten sie eine praktische Lösung für Displays, die in Umgebungen eingesetzt werden, in denen die Direktbeleuchtung nicht gesteuert werden kann.

AR (Anti-Reflexion) Beschichtung

Was ist eine Anti-Reflexion-Beschichtung?

AR-Beschichtung reduziert die Reflexivität von Glas und erhöht die Transmissivität durch optische Beschichtungstechnik.

Mechanismus hinter Reflexionsreduktion in AR-Beschichtungen

Es kann die Durchlässigkeit des Glases auf maximal mehr als 99% erhöhen und die Reflexivität auf weniger als 1% steuern. Dies wird durch mehrere dünne Schichten erreicht, die auf das Glas aufgebracht werden, die eingehende Lichtwellen stören und effektiv Reflexionen aufheben.

Vorteile und Überlegungen von AR-beschichtetem Glas

AR-Beschichtungen verbessern die Klarheit der Anzeige erheblich, indem sie mehr Licht vom Bildschirm durchlaufen lassen und unerwünschte Reflexionen minimieren. Durch die Verbesserung der Glasübertragung wird das Bild des Displays deutlicher dargestellt und wir können eine bequemere Vision genießen. Diese Beschichtungen können jedoch im Vergleich zu anderen Behandlungen teurer und empfindlicher sein.

AF (Anti-Fingerabdruck) Beschichtung

Was ist eine Anti-Fingerabdruck-Beschichtung?

AF-Beschichtung ist eine Schicht von Nanomaterialien auf der Oberfläche des Glases durch Nachahmung des Lotusblatteffekts. Die Nano-Beschichtung bietet hydrophobe Eigenschaften, die Feuchtigkeit und Öle abstoßen.

Wie AF-Beschichtungen Öle und Schmutze abstoßen

Die Oberfläche ist stark hydrophob und kann Ölflecken und Fingerabdruckresten widerstehen. Dies erleichtert die Sauberkeit auf Touchscreens ohne häufiges Wischen.

Haltbarkeit und Wartungsaspekte von AF-Oberflächen

AF-Beschichtungen sind für häufige Interaktionen konzipiert. Es ist glatt und bequem zu berühren. Obwohl sie unter normalen Gebrauchsbedingungen langlebig sind, kann übermäßiger Abrieb ihre Wirksamkeit im Laufe der Zeit verschleißen.

Wie kann man AG/AR/AF Glas schnell identifizieren?

Das Verständnis der Erkennung jedes Typs hilft bei der Überprüfung der Produkteigenschaften während der Installation oder Wartung.

Visuelle und taktile Hinweise zur Identifizierung jedes Typs

AG Glas durch Textur und Lichtdiffusion identifizieren

Legen Sie ein Stück Glas unter eine Tageslampe, dann sehen Sie die Lampe aus dem Glas. Ist das Licht gestreut, ist es eine AG-Oberfläche; Und wenn das klar sichtbar ist, ist es nicht.

Erkennung von AR-Glas durch Farbton und Klarheit

Stellen Sie ein Stück gewöhnliches Glas bzw. AR-Glas vor den Computer. Das Bild durch AR-Glas zeigt sich deutlicher als durch gewöhnliches Glas.

Erkennung von AF-Glas durch Glattheit und Schmutzbeständigkeit

Wassertropfen auf der Glasoberfläche, wenn das Wasser frei rollen kann, ist dies die AF-Oberfläche. Verwenden Sie einen Fettstift, um Linien auf der Oberfläche des Glases zu zeichnen, es ist schwer, auf der Oberfläche mit einer Anti-Fingerbeschichtung zu markieren.

AG Glas

Allgemeine Anwendungen von AG behandelten Displays

Blendenschutzbrillen werden häufig für LCD-Anzeige im Freien oder Anzeige unter starkem Licht verwendet. Wie Werbebildschirme, Geldautomaten, Kassen, medizinische B-Ultraschall-Displays, E-Book-Leser, U-Bahn-Ticketkassen usw. Diese Anwendungen profitieren von reduzierter Blendung für eine bessere Benutzerinteraktion unabhängig von der Umgebungsbeleuchtung.

AR Glas

Anwendungsfälle, in denen die Reflexionskontrolle kritisch ist

Anti-Reflexionsglas wird weit verbreitet in HD-Displays, Fotorahmen, Handys und Kameras verschiedener Instrumente, vorderen und hinteren Windschutzscheiben von Autos, der Solarphotovoltaikindustrie usw. In Fällen, in denen Bildtreue oder Sonnenlichtlesbarkeit am wichtigsten sind, wie z. B. Automobildashboards oder professionelle Monitore, sind AR-Beschichtungen unerlässlich.

AF Glas

Szenarien, die Fingerabdruckbeständigkeit erfordern

Anti-Fingerabdruckbeschichtung kann auf alle Touchscreens angewandt werden und muss nur auf der Vorderseite des Glases (nicht-Zinnseite) sein. Smartphones, Tablets, Kioske an öffentlichen Orten – alle profitieren von AF-Beschichtungen, die die Bildschirmsauberkeit auch nach wiederholten Berührungen erhalten.

Anwendungstipps

Um visuelle Störungen zu reduzieren und bessere visuelle Effekte in verschiedenen Szenarien zu erzielen. Die Terminal-Konstruktion wählt in der Regel eine Kombination aus mehreren Beschichtungen Oberflächenbehandlungen des LCD. Auf die Oberfläche der AG können wir auch eine AR-Beschichtung auftragen oder andere Kombinationen wie AG AF, AR AF und AG AR AF auftragen.

Diese Schichtkombinationen ermöglichen es Designern, Displays sowohl für Umweltherausforderungen (wie Sonnenlicht) als auch für die Benutzerinteraktion (Berührungsempfindlichkeit) zu optimieren.

kaufen Sie das beste LCD-Display von Kadi Display: kontaktieren Sie uns, um Ihre Anfrage zu senden

Kadi Anzeige bietet maßgeschneiderte Lösungen, die TFT-LCD-Module mit Touch-Panels (CTP), Hintergrundbeleuchtung für Helligkeitsstufen bis zu 2500nits für die Sichtbarkeit im Freien integrieren. Wir haben das Abdeckglas als Ihre Anfrage gemacht. LOGO/Farbe/Form/Dicke Ihre Fabrik unterstützt vollständige Anpassung einschließlich Pinout-Designänderungen (FPC und Kabel anpassen) oder Schnittstellentypen wie LVDS/MIPI/HDMI/VGA/USB-A (Schnittstelle anpassen). Für leistungsstarke Displays mit erweiterten Beschichtungen wie Anti-Glare oder Anti-Fingerabdruck-Optionen bereits integriert (10,1" TFT LCD Touchscreen Anti-Glare mit 850nits, 12,3 Zoll1920 *720 TFT LCD mit kapazitiver Touchscreen AF-Behandlung)—wenden Sie sich noch heute für eine Beratung an, die auf Ihre Projektbedürfnisse zugeschnitten ist.

Neueste Blog & Nachrichten

- Ein Schritt-für-Schritt-Leitfaden zum Mastering von MIPI DSI

- Wählen Sie das beste Display für Ihr Embedded-Gerät

- Erfahren Sie mehr über die industrielle LCD-Bildschirmgröße und -Aspektverhältnis

- Sonnenlichtlesbare Displays – die wichtigsten Parameter von Outdoor-LCD-Displays, die Sie wissen müssen

- Stretched Bar LCD Displays Guide: Kosten, Installation & Hauptvorteile