Anzeigemodule — ab TFT LCD-Bildschirm zu OLED und Touch-Integrated Displays – spielen eine entscheidende Rolle in Industrie-, Medizin-, Automobil- und Embedded-Systemen. Die Leute entwerfen diese Module, um auch unter schwierigen Bedingungen stetige visuelle Ergebnisse zu liefern. Dieser Artikel erläutert, wie diese Displays funktionieren, ihre Stärken und Schwächen, wie sie sich voneinander unterscheiden und wo sie am besten funktionieren.

Die Kenntnis der grundlegenden Ideen hinter verschiedenen Displays hilft Ingenieuren, den richtigen für ihre Projekte zu wählen. Es zeigt auch, wie qualifizierte Fertigung und maßgeschneiderte Konstruktionsdienstleistungen die Endleistung beeinflussen. Im Folgenden erscheinen die einfachen Arbeitsprinzipien gängiger Anzeigetypen deutlich, zusammen mit nützlichen Vergleichen und Tipps zur klugen Auswahl.

1. Verständnis des Arbeitsmechanismus moderner Anzeigemodule

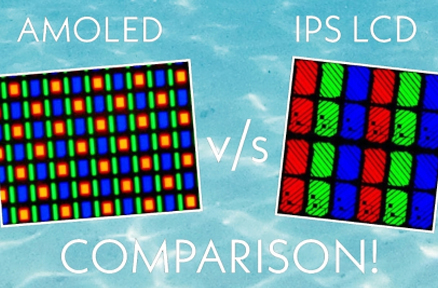

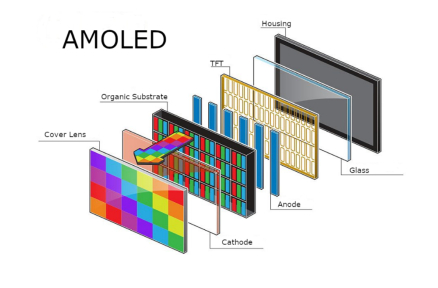

Die meisten industrielle Anzeigemodule enthalten mehrere Schichten. Dazu gehören eine Hintergrundbeleuchtung, ein Flüssigkristall oder eine lichtemittierende Pixelschicht (wie in OLED), Treiberschaltungen und oft ein Touchsensor. TFT-LCD-Module steuern Flüssigkristalle mit elektrischen Feldern. Diese Aktion lässt entweder das Licht passieren oder blockiert es von der Hintergrundbeleuchtung, um Bilder zu erstellen. Kleine Transistoren verwalten jedes Pixel. Sie ändern die Spannung, um das Bild genau zu gestalten.

Auf der anderen Seite, OLED-Displays Licht direkt innerhalb jedes Pixels erzeugen. Daher benötigen sie keine separate Hintergrundbeleuchtung. Diese Funktion bringt tiefere Schwarze, stärkeren Kontrast und in der Regel bessere Blickwinkel.

Viele Anzeigemodule fügen jetzt Touch-Funktionen hinzu. Sie verwenden resistive, kapazitive oder projektierte kapazitive (PCAP) Methoden. Diese Schichten erkennen Fingerbewegungen, während der Bildschirm hell und klar bleibt.

Standardanschlüsse wie HDMI, MIPI DSI, LVDS, eDP oder paralleles RGB verbinden die Module mit den Mainboards. Solche Verbindungen passen perfekt zu eingebetteten Prozessoren, Mikrocontrollern oder industriellen Computern. Wenn Strom fließt, drehen Pixel entweder Licht (in LCD) oder leuchten von selbst (in OLED). Der Bildschirm frischt sich jede Sekunde mehrmals auf. Der Panel-Typ, die Verbindungsmethode und die Treiberqualität entscheiden über die Aktualisierungsgeschwindigkeit, den Farbraich und die schnelle Reaktion.

2. Schlüsselvorteile von industriellen Anzeigetechnologien

Industrielle Anzeigemodule bieten klare Vorteile, die sich gut für harte oder spezielle Aufgaben eignen:

-

Maßgeschneiderte LeistungDiese Designs bewältigen große Temperaturschwankungen, starke Vibrationen und bleiben jahrelang zuverlässig.

-

AnpassungFabriken bieten oft kundenspezifisches Abdeckglas, hellere Bildschirme, verschiedene Anschlüsse und spezielle Formen, so dass das Modul reibungslos zum Produkt passt.

-

Breite TechnologieunterstützungAnwender können TFT-LCD-, OLED- oder hochhelle Panels je nach Geschwindigkeit, Schärfe, Kontrast oder geringem Strombedarf wählen.

-

Konsistenz und QualitätskontrolleStrenge Produktionsregeln (ISO9001, ISO14001, ISO13485, IATF16949) halten jede Einheit vertrauenswürdig und erfüllen Regeln für medizinische und Automobilbereiche.

-

Unterstützung für mehrere SchnittstellenVerschiedene Anschlussmöglichkeiten erleichtern die Verknüpfung mit verschiedenen Systemen.

Dank sorgfältiger Konstruktion arbeiten diese Displays an schwierigen Orten – von Krankenhausmonitoren bis hin zu Fabrikkiosken. Extra Helligkeit und optische Verklebung helfen Menschen, den Bildschirm in hellem Licht zu lesen. Diese Schritte schützen auch besser vor Staub und Feuchtigkeit.

Potenzielle Einschränkungen und Nachteile einiger Paneltypen

Selbst starke industrielle Displays haben einige Nachteile, die es wert sind zu wissen:

-

FarbreproduktionEinige billigere oder ältere TFT-LCD-Panels zeigen Farben weniger genau als High-End-Home-Fernseher.

-

BlickwinkelFarben und Kontrast können verblassen oder sich verschieben, wenn Menschen von der Seite aus schauen. Dies ist wichtig, wenn mehrere Benutzer zusammen schauen.

-

StromverbrauchLCD-Bildschirme mit Hintergrundbeleuchtung verbrauchen in der Regel mehr Energie als OLED-Panels. Batteriegeräte spüren den Unterschied.

-

Kosten für erweiterte FeaturesSuperhelle Bildschirme, harte Abdeckungen, optische Verklebung oder glatte Multi-Touch-Schichten erhöhen den Preis.

Jeder Nachteil hängt vom Job ab. Zum Beispiel zählt die perfekte Farbe weniger auf einer Fabriksteuerung als auf einem Fotobearbeitungsmonitor. Diese Punkte zu kennen hilft Teams, kluge Entscheidungen zu treffen.

4. Vergleich von Display-Technologien für Embedded und medizinische Anwendungen

Verschiedene Anzeigetypen funktionieren auf einzigartige Weise und passen besser zu bestimmten Aufgaben:

-

TFT-LCDsSie finden ein gutes Gleichgewicht zwischen Preis und Zähigkeit. Viele wählen sie für Fabriksteuerungen, Bedienerbildschirme und eingebettete Geräte.

-

OLED-DisplaysSie liefern einen reichen Kontrast und wahre Schwarze. Solche Eigenschaften leuchten in speziellen Werkzeugen und stilvollen Schnittstellen.

-

Kapazitive Touch DisplaysSie ermöglichen natürliche Fingersteuerung und Multi-Touch-Bewegungen in neueren Systemen.

Für eine lange Lebensdauer und eine stabile Arbeit unter Hitze, Kälte oder Schütteln gewinnen TFT-LCDs in industrieller Qualität oft. Doch OLED zeichnet sich aus, wenn Schönheit, tiefe Schwarze und weite Winkel am wichtigsten sind.

Die Ingenieure überprüfen auch die Aktualisierungsgeschwindigkeit, die Treiberstützung, die Helligkeit und die Verbindungstypen. Ein sorgfältiger Blick stellt sicher, dass der gewählte Bildschirm sowohl praktische als auch komfortable Bedürfnisse erfüllt.

5. Ideale Anwendungsfälle und Anwendungen von erweiterten Anzeigemodulen

Erweiterte Anzeigemodule bedienen viele wichtige Bereiche:

-

Industrielle AutomatisierungFabriksteuerungen, Prozessmonitore und Messgeräte benötigen Bildschirme, die Staub, Lärm und raue Handhabung überleben.

-

Medizinische GerätePatientenmonitoren, Diagnosebildschirme und Bildgebungseinheiten erfordern höchste Zuverlässigkeit und ordnungsgemäße Zertifizierungen.

-

Automobil und VerkehrAutoarmaturenbrett, Unterhaltungsbildschirme und Bedienfelder verwenden Module, die Hitze und Vibrationen widerstehen.

-

Embedded ComputingBildschirme, die mit kleinen Boards wie dem Raspberry Pi verbunden sind, verfügen über flexible Verbindungen wie HDMI oder MIPI für kundenspezifische Projekte.

Jedes Feld erfordert spezifische Stärken – lange Betriebsjahre, einfache Verbindungen, benutzerdefinierte Formen und freundliche Berührungssteuerungen.

6. Zukünftige Trends und Entwicklungen in Display-Technologien

Die Anzeigewelt bewegt sich weiter, weil Benutzer bessere Bilder, geringeren Stromverbrauch und einfachere Montage wünschen:

-

Höhere Auflösung: Mehr Pixel bringen scharfere Details für medizinische Untersuchungen und Datenanalysen.

-

Advanced Touch Technologies: Projektierte kapazitive Berührung wird normal für eine reibungslose Steuerung in Fabriken und Krankenhäusern.

-

Kundenspezifische Integration: Hochflexible Module verkürzen die Konstruktionszeit und helfen den Produkten, sich auszeichnen.

-

Verbesserte Haltbarkeit: Bessere Verklebung und stärkere Abdeckungen öffnen Türen für Outdoor und harte Einstellungen.

Neue Ideen wie AR-geführte Reparatur und biegbare Bildschirme deuten auf noch spannendere Optionen hin. Mixed-Technologie-Module werden weiterhin die Bar heben.

Häufig gestellte Fragen

Was unterscheidet industrielle Anzeigemodule von Verbraucheranzeigen?

Industrielle Module sind langlebig, arbeiten in extremer Hitze oder Kälte, überleben raue Bedingungen und bieten viele Anschlussmöglichkeiten. Sie tragen zusätzliche Zertifizierungen und strengere Qualitätskontrollen, die in Haushaltsprodukten nicht üblich sind.

Sind berührungsfähige Panels für hochpräzise Steueraufgaben geeignet?

Ja – kapazitive und projizierte kapazitive Touchpanele reagieren schnell und unterstützen Multi-Touch. Individuelle Einstellungen machen sie perfekt für genaue Aufgaben.

Was sind die neuesten Fortschritte in der industriellen Anzeigetechnologie?

Neue Verbesserungen bringen hellere Bildschirme, intelligentere Touchschichten, geringeren Stromverbrauch, mehr Verbindungsmöglichkeiten und stärkere kundenspezifische Designdienstleistungen.

Welche Einstellungen und Funktionen sollten für industrielle Displays optimiert werden?

Helligkeit und Kontrast müssen dem Umgebungslicht entsprechen. Anschlüsse (HDMI, MIPI, LVDS, etc.) sollten zum System passen. Die Berührungsreaktion erfordert eine Einstellung für den komfortablen täglichen Gebrauch.

Können industrielle Displays im Freien eingesetzt werden?

- Ja. - Ja. Hohe Helligkeit, optische Verklebung und richtige Dichtung lassen sie außen arbeiten. Zusätzlicher Schutz kann bei Regen oder starkem Wetter hinzugefügt werden.

Partner mit einem vertrauenswürdigen Hersteller und Lieferanten

Kadi Anzeige ist ein professioneller Anzeigehersteller, Lieferant und Fabrikpartner mit Sitz in Shenzhen mit über 20 Jahren Branchenerfahrung bei der Herstellung industrieller, medizinischer, eingebetteter und kundenspezifischer Anzeigelösungen. Das Unternehmen bietet eine breite Palette an TFT-LCD, Touch-integrierten Modulen, hochhellen Panels und erweiterten Schnittstellen. Kadi Display kombiniert starke Qualitätssysteme (einschließlich ISO9001-, ISO14001-, ISO13485- und IATF16949-Zertifizierungen) mit fachlicher technischer Unterstützung und flexibler Anpassung, um anspruchsvolle Projektanforderungen zu bewältigen.

Unternehmen, die Qualität und stetige Versorgung schätzen, sind willkommen, mit Kadi Display für maßgeschneiderte Displaylösungen von frühen Ideen bis hin zur vollständigen Produktion zu arbeiten. Erreichen Sie heute für detaillierte Kataloge, maßgeschneiderte Angebote und komplette technische Hilfe während der gesamten Reise.

Neueste Blog & Nachrichten

- Ein Schritt-für-Schritt-Leitfaden zum Mastering von MIPI DSI

- Wählen Sie das beste Display für Ihr Embedded-Gerät

- Erfahren Sie mehr über die industrielle LCD-Bildschirmgröße und -Aspektverhältnis

- Sonnenlichtlesbare Displays – die wichtigsten Parameter von Outdoor-LCD-Displays, die Sie wissen müssen

- Stretched Bar LCD Displays Guide: Kosten, Installation & Hauptvorteile