Heute’ die rasante digitale Welt, LCD-Bildschirme sind überall – von Laptops und Tablets bis hin zu industriellen Monitoren und medizinischen Geräten. Aber nichts stört die Produktivität so wie ein mysteriöser weißer Fleck auf Ihrem Display.

Diese hellen Anomalien sind’ t nur kosmetische Belastungen; Sie können kritische Informationen verschleiern und tiefere Hardware-Probleme signalisieren. In diesem umfassenden Leitfaden, wir’ Tauchen Sie in die Ursachen der weißen Flecken auf LCD-Bildschirmen ein, erforschen Sie effektive Lösungen und bewaffnen Sie mit Präventionsstrategien, um Ihre Displays makellos zu halten.

LCD-Bildschirm weiße Flecken Ursachen

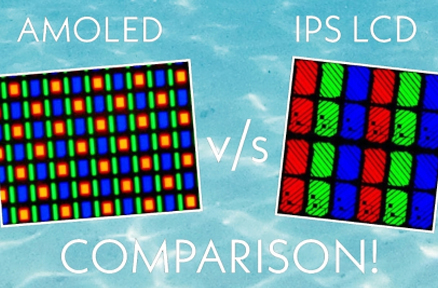

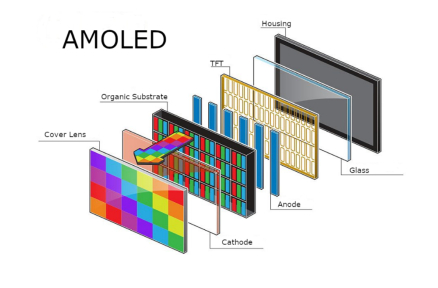

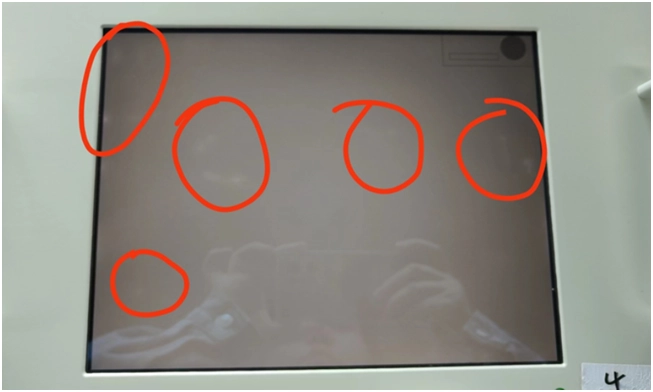

Weiße Flecken auf LCD-Bildschirmen - diese frustrierenden hellen Flecken, die sich weigern zu verblassen - können aus dem Nirgendwo erscheinen und ein nahtloses Seherlebnis in Kopfschmerzen verwandeln. Oft mit einfachen toten Pixeln verwechselt, stammen diese Flecken aus einer Vielzahl von Hardware-Schlucken, die einzigartig für die Flüssigkristall-Display-Architektur (LCD) sind. LCDs verlassen sich auf Schichtplatten, Hintergrundbeleuchtung und präzise Ausrichtungen, um Bilder zu erzeugen, so dass jede Störung in diesen Elementen sich als eine blendende weiße Anomalie manifestieren kann. Lassen Sie’ s brechen die primären weißen Flecken auf dem LCD-Bildschirm ab, so dass Sie das Problem feststellen und es schnell beheben können.

Druckschäden

Ein großer Start für einen weißen Fleck auf einem LCD-Bildschirm ist zu viel Druck. Denken Sie darüber nach, Ihren Laptop Top hart zu schließen. Oder versehentlich ein schweres Buch darauf setzen. Diese kleinen Dinge können die dünnen LCD-Platten unter das Glas drücken. Dieser Druck bewegt die Flüssigkeitsstücke falsch. Oder es verletzt die Lichtfilter Filme. Dies macht kleine helle Flecken. Licht kommt nicht einmal dort heraus. In Fabrikstellen, wo starke Bildschirme grob verwendet werden, passiert dies mehr. Es kommt aus Shakes oder Stacks in kleinen Arbeitsbereichen.

Der Push-Schaden zeigt sich nicht sofort. Es kann Stunden oder Tage später kommen. Der verletzte Ort beruhigt sich dann. Stellen Sie sich ein komplettes Büro vor. Eine linke Wasserflasche auf einem geschlossenen Werkzeug die ganze Nacht kann der ruhige Böse sein. Screen-Fix-Profis sagen, dass bis zu 40% der weißen Flecken-Berichte aus diesem Push-Stress stammen. Dies zeigt, dass Sie Sorgfalt brauchen, wie Sie Dinge halten. Dies gilt für Zuhause oder Arbeit.

Hintergrundbeleuchtung Probleme

Jedes helle LCD-Bild hat eine Hintergrundbeleuchtung hinter sich. Dies ist ein gleichmäßiges LED- oder CCFL-Set. Es beleuchtet das Blatt von innen. Wenn dieser Teil bricht, macht er eine helle Spur auf dem LCD-Bildschirm. Es sieht aus wie ein nebelliger Ring oder starker Glanz. Falsche Liniendiffusoren können dies tun. Dies sind Bettwäsche, die Licht gleichmäßig verbreiten. Oder schlechte LED-Gruppen können Hot Spots machen. Dies geschieht eher, wenn die Hitze von zu heiß wächst. Oder aus einem Sturz.

In kranken Stellen, wo genaue Arbeit am wichtigsten ist, können Hintergrundbeleuchtungsprobleme die Kontrollarbeit verletzen. Dies macht es zu einer großen Sorge. Dinge wie lange hohe Lichtlauf beschleunigen Verschleiß. Dies führt zu nicht einmal Licht im Laufe der Zeit. Wenn Ihr Bildschirm’ Der weiße Fleck wird in dunklen Räumen stärker. Oder wenn es sich mit Winkeldrehungen bewegt, ist die Hintergrundbeleuchtung die schlechte.

Staub oder Müll

Der Staub sieht klein aus. Aber in der geschlossenen LCD-Welt schleicht es sich schlecht ein. Kleine Stücke können durch Luftlöcher hineingehen. Oder während der Bauzeit. Sie kleben zwischen Blattschichten. Sie biegen Licht, um harte weiße Flecken zu machen. Dies passiert häufig in schmutzigen Geschäften oder Räumen ohne Luftreinigung. Luftbits fahren auf Ihren Händen oder Werkzeugen.

Im Laufe der Zeit macht die statische Kraft es schlimmer. Es zieht mehr Müll. Dies macht den Spot Show mehr. Ein Zeichen? Die Marke kann sich etwas ändern, wenn Sie den Bildschirm tippen. Bits innen bewegen. Um dies in geschäftlichen Setups zu stoppen, machen Sie häufig saubere Arbeit. Wie regelmäßig Luftsysteme überprüfen. Das reduziert die Chance sehr viel.

Herstellungsdefekte

Nicht alle weißen Flecken sind benutzerinduziert. Manche werden in der Fabrik geboren. Unvollkommene Panel-Montage - wie ungleichmäßige Klebstoffaufnahme oder mikroskopische Lufttaschen - kann zu inhärenten weißen Flecken auf dem LCD-Bildschirm führen, die kurz nach dem Entboxen auftauchen. Hochvolumenfertigungslinien, obwohl effizient, liefern gelegentlich diese Mängel, die sich sogar auf Premiummarken auswirken.

Für Unternehmen, die Flotten von Displays einsetzen, ist es entscheidend, diese frühzeitig über Qualitätssicherungsprotokolle zu erkennen. Garantieansprüche decken oft solche Mängel ab, aber ihre Identifizierung erfordert Wachsamkeit während der ersten Einrichtung. Allein im Jahr 2024 trugen Fertigungsabweichungen zu Tausenden von Renditen bei, was die Bedeutung der Beschaffung von zertifizierten Lieferanten unterstreicht.

Alterungskomponenten

Alle Technologien werden langsam alt. Aber dann hört es auf. Im Laufe der Jahre brechen Kleber ab. Lichtfilter werden gelb. Hintergrundbeleuchtung verblasst nicht einmal. Dies macht weiße Flecken. Licht verbreitet sich wild. Welt Dinge wie nasse Luft oder Sonnenlicht beschleunigen dies. Dies gilt für außerhalb oder feuchte Fabrikjobs.

Aufwärme und Abwärme Zyklen verletzen Dichtungen. Sie machen winzige Risse. Für eine lange Lebensdauer denken Sie an 30.000-50.000 Stunden Laufen. Dann beginnt der kleine Verschleiß. Aber genau beobachten kann es länger dauern. Kurz gesagt, das Alter verwandelt einen sauberen Bildschirm in ein Chaos von Markierungen, wenn Sie die Pflege überspringen.

Weiße Flecken beheben

Finden Sie einen weißen Fleck auf Ihrem LCD-Bildschirm? Das bedeutet keine großen Probleme. Mit einem Plan Weg, viele Probleme beheben ohne viel Geld oder stoppen Arbeit. Von zu Hause versucht, pro Hilfe, hier ist, wie man LCD-Bildschirm weiße Flecken gut behebt. Denken Sie daran, warten ist der Schlüssel. Eile dich kann schaden, den du tun kannst’ t beheben.

Identifizieren Sie die Ursache

Finden Sie das Problem ist die Grundlage jeder guten Lösung. Beginnen Sie mit dem Spot. Bleibt es bei allen Lichtniveaus oder Wendungen? Stellen, die sich nicht bewegen, sagen Hardware. Diejenigen, die blinken, können weiche Probleme sagen. Starten Sie im Safe Run-Modus. Oder einen Außenbildschirm anschließen. Das schneidet das Problem aus. Wenn der weiße Fleck auf der Außenseite geht, ist Ihr LCD-Blatt das Hauptschlecht.

Schreiben Sie alles mit Bildern und Zeiten auf. Dies hilft groß für kostenlose Behebungsansprüche oder Pro-Gespräche. Für Geschäftsbenutzer fügen Sie Check Soft wie HWMonitor hinzu. Es schreibt seltsame Dinge auf. Das macht Gruppenuntersuchung einfach.

DIY Lösungen

Für kleine LCD-Bildschirm weiße Flecken Fälle, können Sie zu Hause beheben. Wenn Staub schlecht ist, holen Sie ein weiches Tuch und mischen Sie Alkohol und Wasser. Weich in Runden abwischen. Sprühen Sie nie direkt auf. Neuanfangen löscht kurze Probleme. Aktualisieren Sie Treiber über den Gerätemanager unter Windows. Oder Systemeinstellungen unter macOS. Dies setzt den Bildschirm wieder aus.

Für Batteriewerkzeuge funktioniert ein vollständiger Neustart. Nehmen Sie die Batterie für 5 Minuten aus. Diese Linien teilen sich richtig. Diese Schritte beheben 20-30% der weichmachen Flecken aus Tech-Gesprächen. Aber wenn das Zeichen bleibt, halte hier auf. Home Open kann Ihre Free Fix beenden.

Professionelle Reparatur

Wenn Heimwege verpassen, machen Profis am besten. Geprüfte Fix-Leute verwenden spezielle Werkzeuge. Sie öffnen Bettwäsche. Sie Linie Backlights. Oder Streuer ohne zusätzlichen Schaden wechseln. Geldwechsel: $100-$300 für Fixes. Versus $200-$800 für neue. Dies hängt von Größe und Typ ab.

Verwenden Sie kostenlose Fixes von make cover für build-Fehler. Suchen Sie nach Geschäften mit sauberen Räumen, die ISO-Regeln erfüllen. Für staubfreie Arbeit. In Fabrikstellen reduziert die Hilfe vor Ort die Stillstandszeit. Schlüssel zum ganztägigen Laufen. Nach der Reparatur, suchen Sie nach 90-Tage sicher. Das gibt Ruhe.

Was zu vermeiden ist

Schnelle tapfere Bewegungen gehen schief. Stechen Sie den Platz nicht mit Stöcken. Es drückt Müll tiefer. Verwenden Sie keine Reinigungsmittel mit Ammoniak. Sie verletzen Decken. Öffnen Sie Boxen ohne sicheren Power Guard zapps dünne Drähte. Diese Fehler machen nicht nur Flecken schlimmer. Sie bringen Rechtskämpfe in Geschäftsrisikopunkten. Also wählen Sie den sicheren Weg.

Verhindern Sie den weißen Fleck des LCD-Bildschirms

Kleiner Stopp schlägt großen Fix. Dies gilt für Bildschirme, die viel kosten. Setzen Sie gute Wege in Ihren Tag. Dies schützt vor weißen Flecken auf dem LCD-Bildschirm. Es bleibt klar und schneidet Geld im Laufe der Zeit.

Handle mit Sorgfalt

Soft Hold ist deine erste Wache. Bewegen Sie Werkzeuge in weichen Beuteln. Skip fällt den Stoß drinnen. In gemeinsamen Arbeitsplätzen erstellen Sie keine Stapelbereiche. Gute Ständer schneiden Scharnier Push. Eine gemeinsame verletzte Art.

Richtig reinigen

Staub kämpft gegen dich. Verwenden Sie Tuche ohne Statik und Sprays, die dem pH entsprechen. Jede Woche wischen, um den Aufbau zu stoppen. Aber immer zuerst abschalten. Verwenden Sie an sauberen Stellen wie Testräumen Luftdosen aus der Presse vorsichtig.

Bildschirmschützer verwenden

Diese ruhigen Guten stoppen Kratzer und Bits. Wählen Sie harte Glasarten mit Öl-Push-Coats. Für einfache Reinigung. Ändern Sie jedes Jahr, damit es funktioniert.

Sicher aufbewahren

Weltprüfung ist groß: 50-70°F und < 60% Nassluft. In Abdeckungen auf das Regal legen. Weit weg von heißen Dingen. Deine Bildschirme bleiben sauber.

FAQ (häufig gestellte Fragen)

Was bewirkt, dass ein weißer Fleck plötzlich auf einem LCD-Bildschirm erscheint?

Ein weißer Fleck erscheint oft nach Druck oder Aufprall. Manchmal entsteht Staub oder ein Hintergrundbeleuchtungsproblem. Alternde Teile können auch dieses Problem verursachen. Benutzer sollten auf jüngste Tropfen oder schwere Gegenstände auf dem Gerät überprüfen.

Wie kann jemand erkennen, ob ein weißer Fleck durch Staub oder Hardwareschäden entsteht?

Staubflecken können sich beim Reinigen des Bildschirms bewegen oder ändern. Hardware-Schäden verursachen Flecken, die an derselben Stelle bleiben. Benutzer können den Bildschirm sanft reinigen, um nach Staub zu überprüfen.

Sind Sie bereit, Ihr Unternehmen mit zuverlässigen LCD-Lösungen zu schützen? Partner mit Kadi Display heute

In einer Zeit, in der sichere Läufe Arbeit gewinnt, lassen Sie nicht weiße Flecken oder irgendeinen Bildschirm stoppen halten Sie Ihren Shop zurück. Als Top-Business-to-Business-Geber von Fabrik- und kranken LCD-Fixes, Kadi Anzeige in Shenzhen, China, bringt über 20 Jahre Fähigkeit in der Herstellung Hochleistungs-TFT-LCD-Blätter, OLED-Teile, Touch-Add-Bildschirme und voll gefertigte Bildschirmputs.

Erhöhen Sie Ihre Geschäftsanzeigen jetzt: Besuchen Sie www.kadidisplay.com, um unseren Katalog zu erkunden, ein kostenloses Angebot anzufordern oder eine virtuelle Demo zu planen. Kontaktieren Sie unsere Experten noch heute lassen’ s erstellen Displays, die ohne Kompromisse funktionieren. Ihr makelloses Bild beginnt hier.

Neueste Blog & Nachrichten

- Ein Schritt-für-Schritt-Leitfaden zum Mastering von MIPI DSI

- Wählen Sie das beste Display für Ihr Embedded-Gerät

- Erfahren Sie mehr über die industrielle LCD-Bildschirmgröße und -Aspektverhältnis

- Sonnenlichtlesbare Displays – die wichtigsten Parameter von Outdoor-LCD-Displays, die Sie wissen müssen

- Stretched Bar LCD Displays Guide: Kosten, Installation & Hauptvorteile