schermi OLED portare un grande salto avanti nella tecnologia dello schermo. Rimangono molto più sottili e leggeri del vecchio schermi LCDMentre la tecnologia OLED diventa popolare in molti campi, si trasforma in una scelta pratica per tutti i tipi di usi.

Che cos'è un OLED?

OLED, o diodo luminoso organico, agisce come un diodo luminoso. Fai luce quando l'energia passa attraverso la sua parte luminosa. A differenza degli schermi LCD che hanno bisogno di luci posteriori, gli OLED utilizzano sostanze naturali per creare luce immediatamente.

Questa configurazione riduce il consumo di energia, aumenta le differenze taglienti, dà macchie scure profonde e rende i colori appieno e luminosi.

Gli schermi piatti realizzati con la tecnologia OLED si presentano in molte aree. Questi includono gadget domestici, controlli di fabbrica, controlli sanitari e schermi auto. La forma sottile, il basso fabbisogno di energia, le risposte rapide e i grandi angoli di vista rendono gli schermi OLED perfetti per telefoni, orologi intelligenti, schede di controllo, strumenti di laboratorio e pannelli automobilistici.

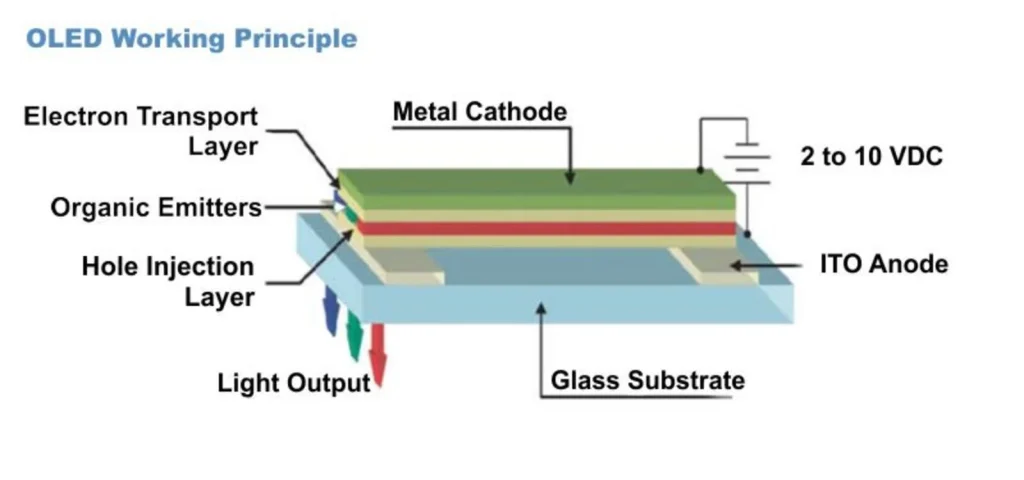

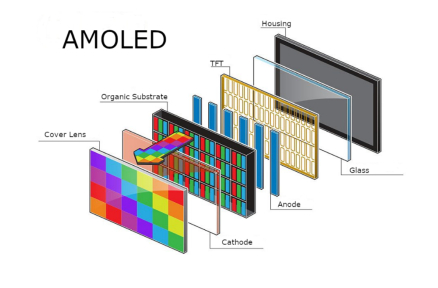

Struttura dello strato OLED

La costruzione di base di uno schermo OLED ha il catodo, l'anodo, lo strato luminoso (la parte naturale che produce la luce) e lo strato di piombo. Queste parti funzionano insieme, aiutando la luce a uscire bene e mantenendo il flusso di energia liscio.

Materiali organici utilizzati negli OLED

Il catodo è uno strato di metallo o piombo che invia elettroni. L'anodo consente al potere di muoversi e spesso utilizza condotti trasparenti come l'ossido di stagno di indio (ITO). Le persone amano ITO per il suo buon flusso di potenza e l'aspetto chiaro.

Tra l'anodo e il catodo si trovano gli strati naturali che fanno luce quando l'energia colpisce. Lo strato di piombo può utilizzare plastiche come la polianilina. Per lo strato luminoso, miscele naturali come Tris (8-idrossiquinolina) alluminio, polifluorene o trifenilamina funzionano come materiali principali. I produttori li scelgono per determinati piani OLED e esigenze di lavoro.

Questi materiali naturali consentono un controllo esatto delle caratteristiche della luce e aiutano la tecnologia ad adattarsi in posti di lavoro duri e ad alta intensità.

Come funzionano gli OLED?

Un OLED funziona come un LED speciale. Il suo strato luminoso proviene da miscele naturali che si illuminano quando l'energia si accende. Questo strato ha una base di plastica bloccata tra un catodo e un anodo. La potenza sveglia i bit naturali e li fa emettere i bit di luce.

Gli OLED agiscono come i LED normali nel concetto, ma cambiano utilizzando strati naturali invece di quelli di roccia dura. Ciò dà piegatura e lavoro migliore. Questa base naturale aiuta a crescere le dimensioni dello schermo e aiuta a montare in fabbrica e usi sanitari.

Come gli OLED producono luce

Gli OLED utilizzano un trucco leggero dall'energia: i materiali brillano quando l'elettricità passa attraverso. Uno strato naturale si trova tra un catodo e un anodo. Quando i volt colpiscono, gli elettroni vanno dal catodo all'anodo. I fori (buone cariche) si muovono in direzione opposta. Si incontrano nello strato naturale, e l'energia esce come pezzi di luce.

Diagramma di come gli OLED producono luce

I volti attraversano il catodo e l'anodo.

Gli elettroni scorrono dal catodo all'anodo.

Questo crea elettroni extra al catodo e forma fori nello strato di piombo.

Si incontrano al bordo del piombo luminoso.

I pezzi di luce escono - vedi luce brillante.

Il colore della luce dipende dalla miscela di materie naturali. Ciò consente modifiche per i lavori che richiedono impostare tipi di luce, come immagini di salute o HUD auto.

Vantaggi OLED

Gli schermi OLED battono gli LCD in molti modi. La loro naturale costruzione sottile e leggera si adatta a sistemi portatili e integrati. Questi includono telefoni, laptop, nastri fitness, set AR / VR e articoli da indossare.

Più grandi angoli di visione e ampi intervalli di calore superiore normale TN LCD. Essi danno pieno divertimento vista. Migliori differenze taglienti rendono le macchie scure profonde e i bordi chiari taglienti. La bassa potenza aiuta la terra. Colori veri e luminosi, risposte veloci e buio reale aumentano il divertimento dell'utente in tutti i campi.

Vantaggi chiave OLED

Costruzione sottile e leggera

Alte differenze acute

Ampio riscaldamento di lavoro

Fare colore brillante

Grandi angoli di vista

Macchie scure profonde

Tempi di risposta rapidi

Bassa necessità di potenza

Queste caratteristiche mettono gli OLED come i migliori adattamenti aziendali nei punti duri, come i controlli di fabbrica e gli strumenti sanitari.

Svantaggi OLED

Nessuna luce posteriore limita la scala luminosa OLED accanto agli LCD. Le viste interne brillano, ma il sole diretto può danneggiare la lettura chiara. Roba naturale usura collegamenti a livelli luminosi - può tagliare la vita in uso pesante.

Fare i passi rimanere duro ora. Essi spingono i costi verso l'alto rispetto al marchio LCD, ma i grandi piani di fabbricazione promettono prezzi più bassi presto.

Principali svantaggi OLED

Vita lavorativa più breve rispetto agli LCD

Pull di potenza superiore con materiale bianco-pesante

Lettura meno chiara al sole diretto

Costi di avvio più alti rispetto agli LCD

Anche con questi problemi, le nuove idee risolvono i punti deboli e aumentano la idoneità per i grandi set aziendali.

Conclusione

La tecnologia OLED cambia i modi dello schermo con pannelli auto-luminosi e piegati. Raggiungono sottili e leggeri mai visti.

Utilizzati in telefoni, TV, monitor, tablet, orologi intelligenti, nastri di fitness, attrezzature per la salute, contatori per auto, set sonori, cuffie, telecamere e scatole da gioco, gli OLED utilizzano curvatura naturale per nuovi piani.

Applicazioni e tendenze future

La tecnologia continua a crescere velocemente. Più aziende scelgono OLED per le sue viste chiare e la bassa potenza. In salute, i medici vedono immagini nitide sugli strumenti portatili. Nelle auto, i conducenti ricevono HUD luminosi che rimangono chiari giorno o notte.

In fabbriche, i controlli rispondono rapidamente e durano in punti caldi o freddi. Kadi Display rimane avanti, aggiungendo nuove dimensioni e livelli di luminosità spesso. Gli acquirenti ottengono parti che soddisfano esigenze esatte. Nessun ordine minimo grande aiuta piccoli test. I campioni veloci accelerano il lavoro e il team tecnico aiuta ad ogni passo.

L’OLED cresce anche nei gadget IoT. I piccoli sensori hanno bisogno di piccoli schermi che sorseggiano energia - OLED lo dà. E si piega per orologi curvi o distintivi rotondi. Colori pop vero. I neri rimangono puri. Nessuna perdita di luce rovina scene oscure in giochi o video.

Ma la cura conta:

Mantenere il luminoso basso quando possibile per allungare la vita. Copertura da sole per uso all'aperto. Scegli buona fabbricazione come Display Kadi Per evitare l'usura precoce. Le loro parti superano test duri e funzionano in polvere, agitazione o aria umida.

Unisciti all'onda OLED

Più acquirenti si uniscono all'onda OLED. Oltre 2.000 aziende si fidano già di Kadi. I nuovi iniziano facilmente: inviare posta o visitare il sito.

Chiedi un preventivo su moduli AMOLED da 15,6 pollici o sottili. Vedi come migliorano il tuo prodotto. Viene una risposta rapida. I campioni vengono spediti rapidamente. Segue il sostegno completo.

OLED guida il futuro degli schermi

Sottile, luminoso, efficiente, perfetto per le esigenze moderne. Unisciti ora e costruisci meglio.

Domande frequenti

Q1: Cosa distingue OLED dalla tecnologia LCD?

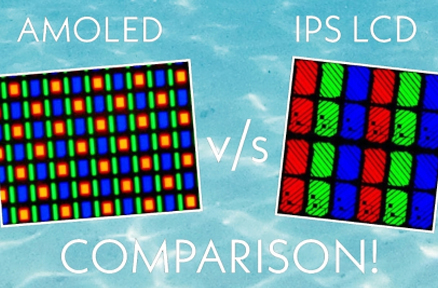

I pannelli OLED illuminano direttamente la luce da materie naturali, senza luci posteriori. Ciò rende forme più sottili e vere scure. Gli LCD hanno bisogno di luci posteriori, utilizzano più potenza e danno meno differenze nitide.

Q2: I display OLED sono adatti per ambienti industriali?

- Sì. - Sì. Gli OLED di fabbrica provenienti da luoghi come Kadi Display gestiscono ampi riscaldamenti. Essi danno alta luminosità per schede di controllo e sistemi auto.

Q3: Come si confronta la durata di vita OLED con LCD?

Gli OLED possono usurare più velocemente ad alta luminosità. Ma i nuovi passaggi estendono l'uso per abbinare o battere gli LCD nei normali lavori.

Q4: Gli OLED possono essere personalizzati per progetti?

Certo. Produttori come Kadi Display forniscono parti OLED adatte con collegamenti come MIPI, LVDS e abilità tattili per risoluzioni e dimensioni impostate.

Q5: Quali applicazioni beneficiano di più da OLED?

Strumenti di salute, pannelli automobilistici e portano guadagno IoT da OLED’ s tagliente, bassa potenza e piega.

Partner con Kadi Display – il tuo produttore e fornitore OLED di fiducia

Kadi Display è un produttore e fornitore OLED leader. Porta nuove risposte di visualizzazione adatte per sollevare i lavori di fabbrica e di salute. Nessuna regola MOQ, i primi modelli veloci e la tecnologia completa rendono il lavoro con Kadi Display semplice ed efficiente.

Raggiungi Kadi Visualizza ora al Sales@sz-kadi.com per richiedere un preventivo.

Scopri come i nostri pannelli AMOLED da 15,6 pollici o i moduli OLED sottili possono migliorare la tua prossima costruzione. Unisciti a oltre 2.000 acquirenti felici: inizia il tuo percorso OLED personalizzato oggi stesso.

Ultimi Blog & Notizie

- IPS vs altri pannelli Come selezionare interfacce di visualizzazione per LCD TFT incorporato e industriale

- Display MIPI DSI da 7 pollici: le migliori specifiche e le migliori scelte nel 2026

- Display TFT ad ampia temperatura per applicazioni industriali

- Come le soluzioni AG, AF e AR risolvono problemi critici di visualizzazione

- Una guida passo-passo per padroneggiare MIPI DSI

Blog & Notizie correlate

-

TN contro IPS2024-7-9

-

TN contro IPS2024-7-9