Le tecnologie di visualizzazione costituiscono la spina dorsale dell'elettronica moderna, consentendo tutto, dai pannelli di controllo industriali ai dispositivi di imaging medico. Al centro di questi sistemi si trova l'indirizzamento dei pixel, un processo che determina come le immagini vengono renderizzate sullo schermo. Due metodi principali dominano questo spazio: le tecnologie a matrice passiva e a matrice attiva. La comprensione di questi approcci è essenziale per i produttori e i fornitori che selezionano componenti per applicazioni affidabili e ad alte prestazioni.

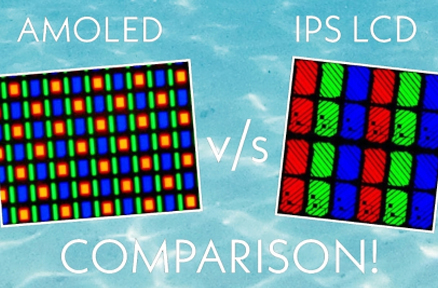

Entrambi LCD e OLED sfruttano strutture a matrice, classificate come LCD/OLED a matrice passiva (PMOLED) o varianti a matrice attiva (AMOLED per OLED, TFT per LCD). Questa guida esplora i display a matrice, i loro principi operativi e un confronto dettagliato per aiutare il processo decisionale informato nei progetti di integrazione dei display.

Cosa sono Matrix Display?

I display a matrice consistono in una disposizione a griglia di pixel, gli elementi fondamentali che emettono luce o modulano la luce che costruiscono contenuti visivi. Questi pixel sono organizzati in righe e colonne, consentendo un controllo preciso per formare testo, grafica o video dinamici. Tali display alimentano un'ampia gamma di dispositivi, tra cui monitor industriali ad alta risoluzione, schermi diagnostici medici e sistemi incorporati nelle attrezzature di automazione.

LCD e OLED utilizzano la tecnologia matrice per la gestione dei pixel. Nei LCD, i cristalli liquidi si tordono per controllare il passaggio della retroilluminazione, mentre gli OLED emettono luce organicamente sulla stimolazione elettrica. Il framework di matrice garantisce un indirizzamento efficiente, dove il multiplexing attiva righe e colonne specifiche per illuminare i pixel mirati. Questa differenziazione – passiva contro attiva – influenza la risoluzione, i tassi di aggiornamento e l’idoneità generale per ambienti esigenti come pavimenti di produzione o strutture sanitarie.

Come funzionano i display Matrix

Le immagini emergono dall'energia selettiva dei pixel all'interno della griglia riga-colonna. Il multiplexing scansiona l'array sequenzialmente: una riga si attiva, seguita da segnali di colonna che dettano gli stati dei pixel. Questo veloce ciclo rinfresca l'intero display più volte al secondo, creando l'illusione di movimento continuo.

I sistemi passivi si basano su intersezioni dirette di elettrodi per il controllo, semplificando l'hardware ma introducendo limitazioni nella precisione. Le configurazioni attive incorporano elementi di commutazione per pixel, migliorando stabilità e velocità. Per i fornitori industriali, cogliere queste meccaniche supporta la selezione ottimale di moduli LCD TFT, come quelli di produttori con sede a Shenzhen specializzati in soluzioni robuste e personalizzate.

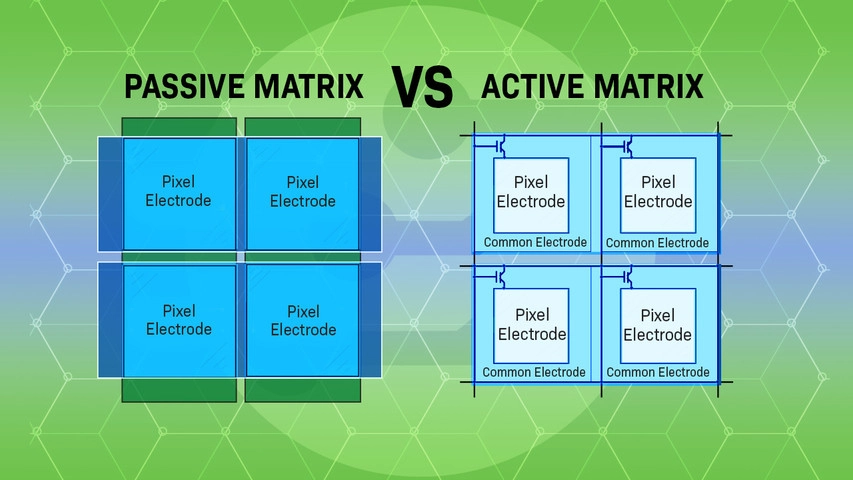

Display a matrice passiva

I display a matrice passiva rappresentano un approccio precedente e semplificato al controllo dei pixel, utilizzando una rete di elettrodi a fila e a colonna senza componenti di commutazione dedicati per pixel. L'applicazione di tensione alle intersezioni attiva i pixel, alterando il loro comportamento ottico per produrre luce o modulare la trasmissione.

Struttura dei display a matrice passiva

L'architettura enfatizza il minimalismo, caratterizzato da:

-

Elettrodi di filaConduttori orizzontali che collegano tutti i pixel in fila, distribuindo i segnali di attivazione in modo uniforme.

-

Elettrodi a colonnaLinee verticali che collegano i pixel della colonna, consentendo la consegna di tensione mirata.

-

Elettrodi PixelPunti di intersezione dove la tensione applicata governa gli attributi del pixel come la luminosità e il colore. Nelle configurazioni LCD, i campi elettrici riorientano i cristalli liquidi per regolare la retroilluminazione; nei OLED, la corrente continua scatena l'emissione.

Questo design a soli elettrodi riduce la complessità, rendendo le matrici passive economicamente efficaci per le implementazioni di base. Tuttavia, l'attivazione involontaria di pixel adiacenti può verificarsi a causa di linee condivise.

Come funzionano i display a matrice passiva

L'operazione dipende dall'indirizzamento basato sulla griglia con m righe di fila e n righe di colonna, totalizzando m n controlli. “ Passivo” indica l'assenza di elementi attivi; I pixel rispondono tramite soglie inerenti ai differenziali di tensione.

Per illuminare un pixel, la selezione simultanea di righe e colonne crea un calo di tensione (V_on per l'attivazione, V_off per la disattivazione). Nei LCD, questo torce i cristalli per consentire o bloccare la luce; nei OLED, eccita gli emittenti proporzionalmente. L'aggiornamento costante impedisce lo sbiadimento, poiché i pixel mancano di ritenzione della carica.

Per i fornitori che si integrano in dispositivi a bassa potenza, questo metodo si adatta bene ai contenuti statici, anche se gli scenari dinamici rivelano ritardi di aggiornamento.

Vantaggi della matrice passiva

-

Produzione a prezzi accessibiliMeno componenti riducono i costi di fabbricazione, ideale per ordini di volume in strumenti industriali entry-level.

-

Consumo energetico ridotto per immagini staticheNessun prelievo continuo del transistor risparmia energia in display immutabili, vantaggioso per i portatili medici a batteria.

-

Semplicità nelle applicazioni di baseLa progettazione semplice facilita la prototipazione rapida per risoluzioni non esigenti.

Svantaggi della matrice passiva

-

Tempo di risposta più lentoLa scansione sequenziale induce ghosting nei contenuti ad alta intensità di movimento, limitando l'uso nei sistemi di monitoraggio a ritmo rapido.

-

Angoli di visione limitatiIl controllo dell'elettrodo fornisce viste ottimali strette, degradando il contrasto fuori asse, inadatto per revisioni mediche collaborative.

-

Rapporti di contrasto inferioriGli spostamenti della scala di grigi riducono la profondità, con i neri che appaiono lavati alla luce ambiente.

Applicazioni Matrix Passive

Questi display eccelleno in scenari a bassa risoluzione e sensibili ai costi: manometri digitali nell'automazione delle fabbriche, imitazioni di carta elettronica per i tracciatori di inventario o semplici termometri medici. Fornitori come Display Kadi offrire varianti passive per tali integrazioni, garantendo affidabilità in budget limitati.

Display a matrice attiva

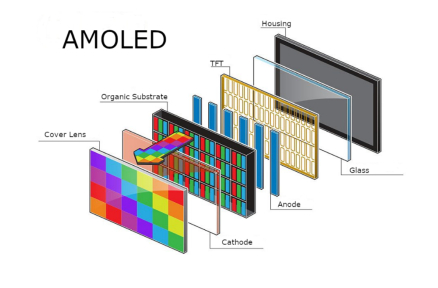

La matrice attiva visualizza la gestione avanzata dei pixel attraverso singoli elementi di controllo, principalmente transistor a film sottile (TFT). Ogni pixel si accoppia con un transistor, consentendo un indirizzamento indipendente per una fedeltà e una reattività superiori.

Struttura dei display a matrice attiva

Gli elementi chiave includono:

-

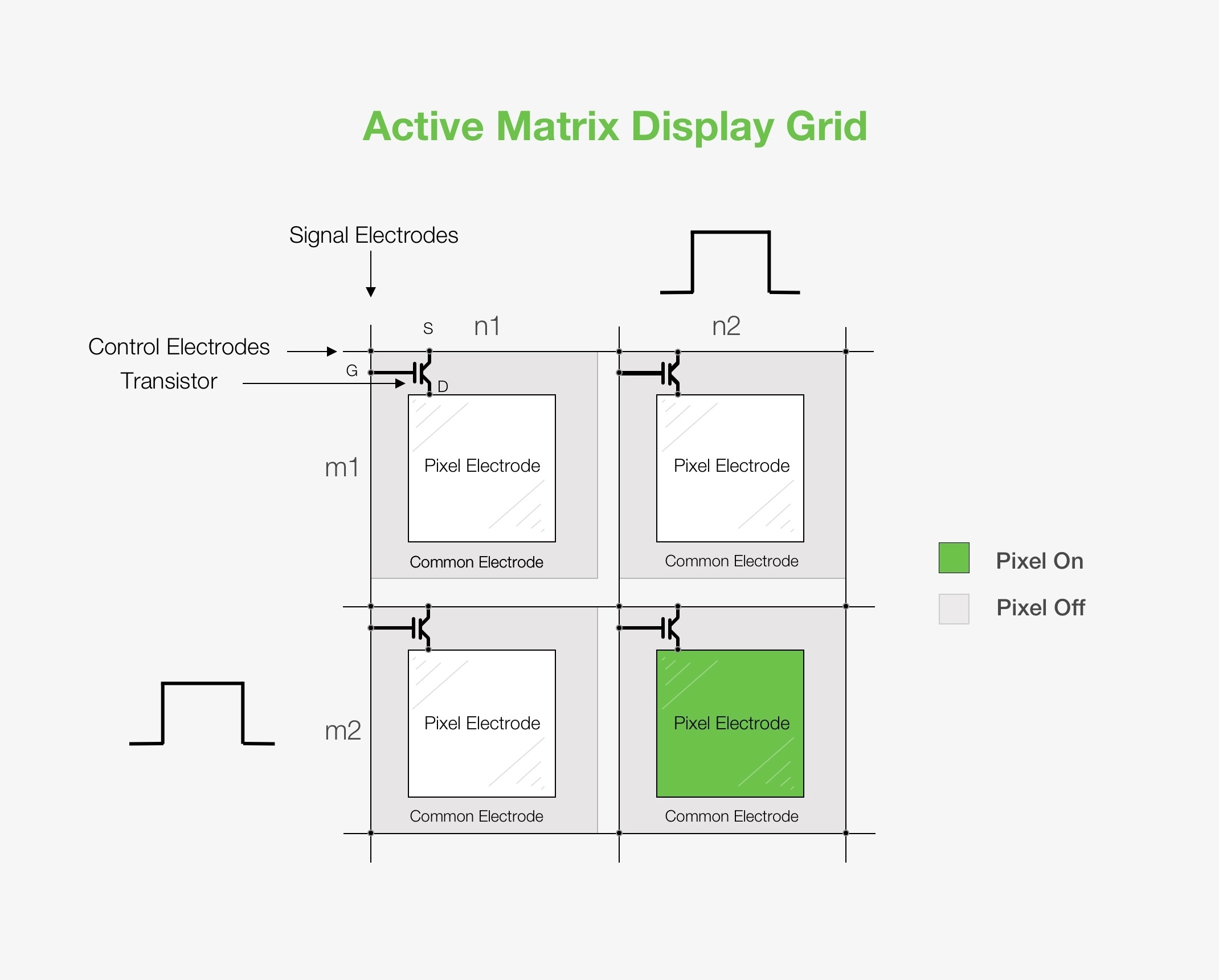

elettrodi segnaleLinee a colonna che forniscono tensioni di dati di immagine ai transistor.

-

Elettrodi di controlloLinee di fila che attivano il transistor.

-

Transistore a film sottile (TFT)Interruttore per pixel con terminali di sorgente, scarico e cancello; la tensione del cancello commuta la conduttività, ricaricando i condensatori del pixel.

-

Elettrodo comunePiano condiviso messo a terra che forma campi con elettrodi pixel.

-

Elettrodo PixelUnico per pixel, carica di sostegno per la modulazione della luce.

Gli strati TFT si depositano sottile su substrati di vetro, integrandosi perfettamente con matrici LCD o OLED.

Come funzionano i display a matrice attiva

Le coppie transistor-condensatore memorizzano gli stati dei pixel dopo l'aggiornamento. La selezione sequenziale delle righe attiva i cancelli, consentendo ai segnali della colonna di caricare i condensatori. Le cariche mantenute persistono, riducendo al minimo il crosstalk e consentendo alti tassi di aggiornamento.

Ciò garantisce un'illuminazione uniforme tra i fotogrammi, fondamentale per le immagini industriali senza flicker. Nei TFT LCD, i campi tordono i cristalli; in AMOLED, guidano gli emittenti organici.

Vantaggi della matrice attiva

-

Qualità di immagine superioreGli stati persistenti producono un alto contrasto e nitidezza, vitali per l'imaging medico preciso.

-

Tempi di risposta rapidiL'indipendenza dei pixel elimina la sfocatura del movimento, supportando i dati in tempo reale nei dashboard di produzione.

-

Ampi angoli di visioneIl controllo uniforme conserva colori e luminosità da prospettive diverse, migliorando l'usabilità nelle configurazioni orientate al team.

Svantaggi della matrice attiva

-

Costi di produzione più elevatiLa fabbricazione di transistor aumenta la complessità e il prezzo, sebbene sia scalabile per ordini di fornitori di massa.

-

Utilizzo elevato di potenzaIl controllo continuo attira più energia, compensata da guadagni di efficienza nel funzionamento dinamico.

Applicazioni Matrix Attiva

Dominando i settori premium, le matrici attive alimentano pannelli HMI industriali di fascia alta, display chirurgici e interfacce automobilistiche. I produttori preferiscono le varianti TFT per la loro robustezza in condizioni difficili.

Matrice passiva contro attiva

Entrambe le tecnologie grigliano pixel per indirizzare, ma divergono nella finezza del controllo. Le matrici passive impiegano reti di elettrodi per l'economia, la reattività di scambio per l'accessibilità, adatta ai manometri industriali statici e a budget. Le matrici attive impiegano transistor per la precisione, fornendo immagini vibranti e stabili a costi più elevati, ideali per schermi medici dinamici e di automazione.

In pratica, le risoluzioni passive sono inferiori a 320× 240 con frequenze di aggiornamento inferiori a 60Hz; active eccelle, supportando 4K e 120Hz. Profili di potenza flip: conserva passivo in attesa, attivo in movimento. Visualizzazione e contrasto favoriscono attivi, con miglioramenti IPS che allargano gli angoli a 178°.

Per le decisioni B2B, le matrici attive si allineano agli standard in evoluzione nei settori incentrati sull’affidabilità, come dimostrano i fornitori certificati ISO che danno priorità alla TFT per la longevità.

Conclusione

La matrice passiva e attiva visualizza ogni nicchia dell'ecosistema di visualizzazione, bilanciando i costi, le prestazioni e le esigenze dell'applicazione. Le opzioni passive semplificano le integrazioni di base, mentre le opzioni attive, in particolare le LCD TFT, aumentano la qualità per esigenze sofisticate. La selezione in base alla risoluzione, all’ambiente e al budget garantisce risultati ottimali nei progetti industriali e medici.

Mentre la tecnologia dei display si evolve, le innovazioni ibride promettono di colmare le lacune, ma i principi fondamentali persistono. Produttori e ingegneri beneficiano di collaborare con fornitori esperti esperti in queste basi.

Domande frequenti

Qual è la differenza tra display a matrice passivo e attivo?

I display a matrice passiva utilizzano una semplice griglia di elettrodi per il controllo dei pixel, rendendoli economicamente efficienti ma inclini a risposte più lente e crosstalk. Gli schermi a matrice attiva incorporano transistor come i TFT per indirizzare singoli pixel, con conseguenti immagini più nitide, velocità di aggiornamento più veloci e angoli di visione migliori.

Quale tecnologia di matrice è migliore per applicazioni industriali?

La matrice attiva, in particolare gli LCD TFT, è preferita per le impostazioni industriali a causa del suo contrasto superiore, dei tempi di risposta e della durata in ambienti ad alte vibrazioni. Le matrici passive funzionano per display statici a basso costo come i sensori di base.

Come gestiscono i display a matrice passive il movimento rispetto a quelli attivi?

Le matrici passive spesso mostrano ghosting da scansione sequenziale, inadatta per contenuti in movimento veloce. Le matrici attive mantengono gli stati dei pixel tramite i condensatori, eliminando lo sfocamento per un video fluido nei sistemi di monitoraggio.

I display a matrice passiva sono ancora utilizzati nei dispositivi moderni?

Sì, in applicazioni consapevoli del budget come calcolatrici, lettori elettronici e semplici dispositivi medici dove l'alta risoluzione è ’ T richiesto.

Che ruolo svolgono le certificazioni nella scelta dei fornitori di display a matrice?

Certificazioni come ISO9001, ISO13485 e IATF16949 garantiscono qualità, affidabilità e conformità, fondamentali per i display industriali e medici per soddisfare gli standard normativi.

Cerchi produttori e fornitori di display? Partner con Kadi Display per soluzioni premium TFT LCD e AMOLED

In qualità di produttore e fornitore leader di display TFT LCD e AMOLED di alta qualità, Kadi Display offre soluzioni a matrice attiva su misura per applicazioni industriali e mediche.

Elevare le prestazioni del progettocontatta il nostro team al Sales@sz-kadi.com o 86-13662585086 per richiedere un preventivo, esplorare la prototipazione o discutere opzioni di incollaggio come adesivo trasparente ottico per una durata robusta. Proteggi display affidabili che guidano efficienza e innovazione oggi.

Ultimi Blog & Notizie

- IPS vs altri pannelli Come selezionare interfacce di visualizzazione per LCD TFT incorporato e industriale

- Display MIPI DSI da 7 pollici: le migliori specifiche e le migliori scelte nel 2026

- Display TFT ad ampia temperatura per applicazioni industriali

- Come le soluzioni AG, AF e AR risolvono problemi critici di visualizzazione

- Una guida passo-passo per padroneggiare MIPI DSI

Blog & Notizie correlate

-

TN contro IPS2024-7-9

-

TN contro IPS2024-7-9