Nelle applicazioni industriali, i display spesso funzionano in ambienti con temperature fluttuanti o estreme. Queste condizioni possono influenzare significativamente le prestazioni, l'affidabilità e la longevità display a cristallo liquido (LCD)Comprendere gli effetti della temperatura sui display e implementare strategie di progettazione adeguate è essenziale per garantire funzionalità e durata ottimali.

Panoramica delle considerazioni di temperatura LCD per applicazioni industriali

Ogni LCD ha una temperatura di funzionamento e di archiviazione specificata elencata nella scheda specifica del display e del suo controller. In genere, questa temperatura è specificata da -20°C a 70°C per la temperatura di funzionamento e da -30°C a 80°C per la temperatura di stoccaggio. Si dovrebbero prendere in considerazione il funzionamento o la conservazione del display vicino alle temperature massime e minime. Gli ambienti industriali, come quelli presenti negli impianti di produzione, nei chioschi all'aperto o nei sistemi automobilistici, spesso espongono i display a questi estremi.

Alte temperature

Effetti delle alte temperature sui LCD

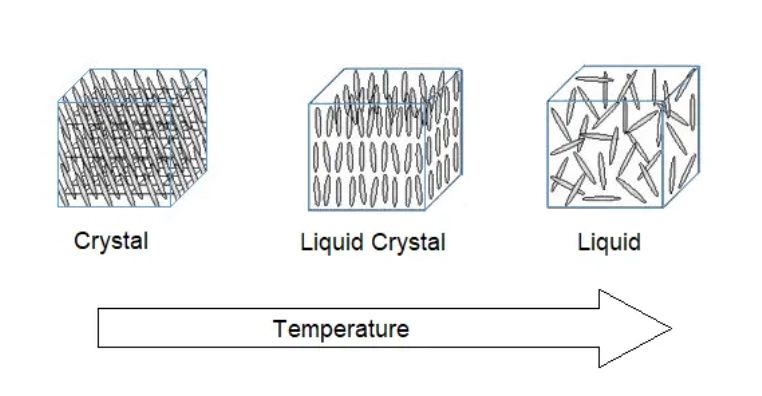

A temperature molto elevate, gli effetti possono essere visti sui componenti elettronici e sul cristallo liquido del display. Gli effetti di un ambiente troppo caldo causeranno un oscurimento del display, visibilità diminuita / limitata, comunicazioni inaffidabili e potenziali danni al circuito integrato a causa di un aumento della conduttività. Il cristallo liquido nel display inizierà a degradarsi a temperature molto elevate.

Il surriscaldamento dello schermo può causare la comparsa di macchie scure o provocare uno schermo completamente scuro. Il contrasto può essere influenzato quando un display viene utilizzato a temperature ultra elevate. Le temperature più elevate provocano un aumento della conduttività. Ciò significa che è necessario meno tensione per fornire lo stesso contrasto ai pixel.

Il cristallo liquido utilizzato nel display può essere disorientato a temperature molto elevate. Questo disorientamento delle molecole di cristallo liquido può provocare un'immagine oscura o parzialmente oscura sul display.

Soluzioni per prevenire il surriscaldamento

Per evitare il surriscaldamento interno ed esterno, ventilatori e ventilatori possono essere integrati nel sistema per mantenere il display nelle condizioni di funzionamento specificate. Le precauzioni per evitare l'ingresso di umidità nel sistema devono essere prese quando si includono le aperture di ventilazione.

I progettisti dovrebbero anche considerare tecniche di gestione del calore come l'uso di retroilluminazione a bassa potenza o l'integrazione di sensori termici che regolano la luminosità in base alla temperatura ambiente.

Basse temperature

Impatto delle basse temperature sui LCD

Un display che viene utilizzato o memorizzato a temperature molto basse avrà gli effetti opposti rispetto alle temperature elevate. Gli effetti delle temperature fredde possono essere visti come un tempo di risposta rallentato, un aumento del consumo energetico, una riduzione del contrasto e un display non operativo.

A basse temperature, il cristallo liquido nel display inizierà a congelarsi. Ciò provoca una ridotta mobilità delle molecole di cristallo liquido e la luce non può passare attraverso come previsto. A differenza di un ambiente molto caldo, il contrasto sarà ridotto a basse temperature.

I semiconduttori che operano a temperature molto basse avranno una conduttività diminuita a causa dell'aumento della resistenza. I tempi di risposta possono anche rallentare i display che vengono utilizzati in ambienti molto freddi.

Come mitigare gli effetti del freddo

Le compensazioni da regolare per ambienti freddi possono includere riscaldatori, regolatori di tensione e termistori per regolare la potenza determinata dalla temperatura. I IC di compensazione della temperatura possono essere inclusi nelle applicazioni su entrambi i raggi dello spettro di temperatura.

Gli alloggi con isolamento o elementi di riscaldamento incorporati sono spesso utilizzati per applicazioni esterne. Inoltre, le regolazioni del firmware possono consentire cicli di riscaldamento graduali prima che inizi il funzionamento completo.

Intervali di temperatura per LCD

Intervali di temperatura comuni per funzionamento e stoccaggio

Gli intervalli di temperatura di visualizzazione comuni possono essere trovati come tre insiemi comuni. Gli intervalli di temperatura possono essere confermati nella scheda tecnica del display e del suo controller. Per i LCD standard di qualità industriale, le gamma tipiche includono:

-

Funzionamento: -20°C a 70°C

-

Conservazione: -30 ° C a 80 ° C

Queste specifiche garantiscono la funzionalità in diversi climi proteggendo i componenti interni.

Gli effetti delle temperature estreme sulle prestazioni e sulla longevità del display

Il funzionamento e la conservazione di un display a temperature superiori agli intervalli specificati possono causare danni permanenti al dispositivo. La fusione delle proprietà del display può verificarsi se il display viene utilizzato o memorizzato a temperature che superano i limiti.

Gli effetti di temperature estremamente basse su un display sono meno probabili di essere permanenti rispetto a temperature calde. Il risultato probabile del funzionamento di un display al di sotto della gamma raccomandata è che il display non si accenderà, eliminando così la possibilità che i circuiti interni si accorciano.

Mantenere il funzionamento entro questi confini non solo preserva la qualità dell'immagine ma prolunga anche la vita del prodotto.

Considerazioni di progettazione per le variazioni di temperatura

Prevenire i danni mantenendo il funzionamento entro i limiti di temperatura specificati

Si raccomanda vivamente di utilizzare e conservare il display entro intervalli di temperatura specificati per evitare di danneggiarlo. Il funzionamento al di fuori di questi limiti può causare malfunzionamento o guasto permanente.

I progettisti devono incorporare test ambientali durante le fasi di sviluppo utilizzando camere termiche che simulano condizioni reali.

Utilizzo di IC di compensazione della temperatura e tecnologie adattative

I IC di compensazione della temperatura possono essere inclusi in applicazioni su entrambi i raggi dello spettro di temperatura. Questi IC aiutano a regolare i livelli di tensione dinamicamente in base alle condizioni ambientali.

Il controllo adattivo della luminosità utilizzando sensori aiuta a ridurre la generazione di calore da retroilluminazione mantenendo al contempo la visibilità, particolarmente utile in display leggibili alla luce solare come i moduli ad alta luminosità di Kadi Display.

Conclusione

La resistenza alla temperatura è fondamentale per qualsiasi soluzione LCD industriale. Che si tratti di degrado indotto dal calore o di lentitudine indotta dal freddo, la comprensione del comportamento termico consente agli ingegneri di selezionare componenti adatti e implementare misure di protezione in modo efficace. Aderendo rigorosamente alle specifiche operative e sfruttando tecnologie adattative come riscaldatori o compensatori, i progettisti di sistemi garantiscono prestazioni affidabili in condizioni ambientali difficili.

Domande frequenti

Q1: Cosa succede se un LCD funziona oltre la sua temperatura nominale?

Il funzionamento e la conservazione di un display a temperature superiori agli intervalli specificati possono causare danni permanenti come lo scioglimento o schermi neri a causa della degradazione del cristallo liquido o del guasto del IC dovuto all'aumento della conduttività.

Q2: Gli effetti del freddo sono reversibili?

- Sì. - Sì. Una volta restituiti all'interno della gamma, la maggior parte dei display riprende la normale funzione poiché il congelamento generalmente non causa danni permanenti a differenza del surriscaldamento.

Q3: Come proteggi gli LCD dal calore esterno?

Ventilatori e ventilatori possono essere incorporati nei contenitori; Tuttavia, la protezione dell'umidità deve essere considerata anche accanto a soluzioni di gestione termica come dissipatori di calore o circuiti di controllo della luminosità adattivi.

Q4: Tutti i tipi di LCD possono gestire ambienti estremi?

No. Esistono alcuni tipi di fluidi specializzati ma sono costosi; I pannelli standard TN seguono i tipici limiti di funzionamento -20 ° C-70 ° C a meno che non siano personalizzati.

Display LCD ad ampia temperatura personalizzati da Kadi Display

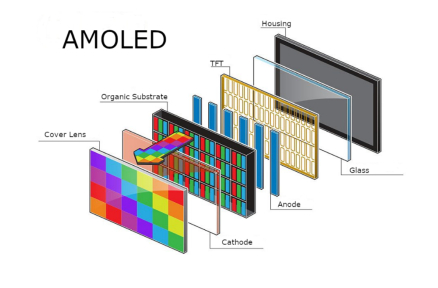

Display Kadi fornisce robusti moduli TFT-LCD ad ampia temperatura progettati appositamente per casi di utilizzo industriali esigenti. I loro prodotti offrono un'eccellente riproduzione dei colori, un'alta durata sotto impatti di pressione, velocità di risposta veloci in condizioni diverse e interfacce personalizzabili tra cui TTL / LVDS / MIPI / EDP / HDMI. La maggior parte dei nostri display ad alta luminosità può raggiungere oltre 800 cd/m², o alcuni addirittura fino a 2500 cd/m², rendendoli ideali per applicazioni leggibili alla luce solare.

Ad esempio, l'IPS TFT LCD ha un angolo di visione fino a 178 gradi, garantendo una chiarezza costante indipendentemente dalla posizione di visione - critica quando utilizzata all'aperto o montata sopra la testa. Abbiamo realizzato AOI durante il processo di fabbricazione FOG, garantendo l'integrità del pixel anche sotto stress termico.Personalizza i servizi includono regolazione della luminosità della retroilluminazione, modellazione del vetro della copertura e legame ottico che migliora la precisione del tocco mentre sigillano contro l'intrusione dell'umidità.

Con oltre due decenni di esperienza, Kadi Display si impegna non solo come fornitore di LCD ma come partner di soluzioni complete che integrano servizi LCM/TP/PCBA su misura per le esigenze delle vostre applicazioni. Contatto Kadi Display Oggi.

Ultimi Blog & Notizie

- Choosing the Best Display for Your Embedded Device

- Learn About the Industrial LCD Display Screen Size and Aspect Ratio

- Sunlight Readable Displays – the Most Important Parameters of Outdoor LCD Displays You Need to Know

- Guida degli schermi LCD a barra allungata: costo, installazione e Benefici principali

- Guida di selezione LCD da 7 pollici: 800×480 a FHD | Display DSI RGB/LVDS/MIPI | Kadi

Blog & Notizie correlate

-

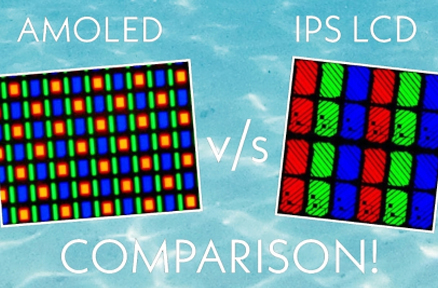

TN contro IPS2024-7-9

-

TN contro IPS2024-7-9