Introduction

A touch screen is an electronic visual display that allows the user to control an electronic device simply by touching the icons on the display. In industrial automation, touch screen technology has transformed how operators interact with machines, replacing traditional hardware inputs like keyboards and mice. The use of a touch screen for HMI ensures efficient functioning, improved user performance, and enhanced productivity. When evaluating capacitive vs resistive touch screens for industrial applications, understanding their differences is essential to choosing the right solution.

What are Resistive Touch Screens?

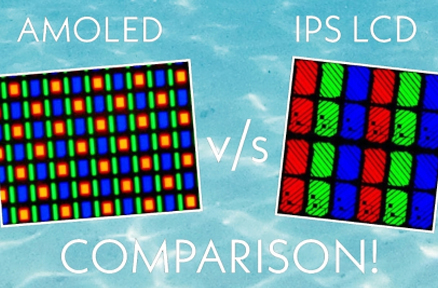

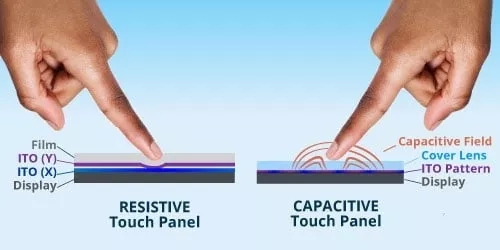

Resistive touch screens have two layers that are either made of PET film or glass/ polycarbonate plastic. Each pairing offers its own specific features. However, both layers have a uniform resistance value over their whole surface. Indium Tin Oxide (ITO), a transparent metal oxide, is deposited on the inner surface of each of the two layers. When pressure is applied to the touch screen, the top layer bends to make contact with the bottom layer. This results in a change in resistance between the two layers and, as a result, a change in current.

Types of Resistive Touch Screens

4-Wire Analog

In a 4-wire analog resistive touch screen technology, both the top and bottom layers have two electrodes (busbars) perpendicular to each other. Using this type of electrical-coordinate configuration in this type, the controller senses the coordinates when the two layers touch each other.

5-Wire Analog

In 5-wire analog resistive touch technology, the bottom layer has four electrodes on four corners. The fifth wire is a sensing wire embedded in the top layer.

8-Wire Analog

The 8-wire sensing circuit is the most sensitive resistive touch screen technology. Each electrode in this touch technology has two wires instead of one. This adds a layer of redundancy to the circuit.

Benefits of Resistive Touch Screens

Resistive touch screens are economical. Because of the design simplicity of the touchscreen and its corresponding controllers. They consume less power as compared to other touch screen technologies. Because resistive touchscreens are pressure-sensitive, they may be used with any input device, such as a gloved hand or a pen/stylus. Resistive touchscreens offer a quick response to the input. Light touches are not detectable by a resistive touchscreen. That’s why resistive touch screens are preferred in an environment when there is the anticipation of accidental touches on the screen.

Drawbacks of Resistive Touch Screens

Resistive touchscreens come with only 75% clarity. They display low-quality images as multiple films are layered in the structuring of these screens. The performance of resistive touch screens is affected by the continuous distortion and warping of the ITO layer. Sharp items, scratching, and poking can easily damage this layer. Resistive touchscreens offer low optical transmissivity (less than 80%).

What are Capacitive Touch Screens?

A capacitive touch screen has an insulator such as glass with a transparent conductor coating. This coating material is usually Indium Tin Oxide (ITO). When there is a touch on the screen, a little amount of charge is attracted to the point of contact. Circuits in each corner of the screen measure the charge and transmit it to the controller for processing.

Types of Capacitive Touch Screens

Surface Capacitive Technology

In surface capacitive technology, the conductive coating is present only on one side of the insulator, and four electrodes are present on four corners of the touchscreen.

Projected Capacitive Technology (PCT)

In this technology, a single layer of conductive material is etched to make an X-Y grid pattern of electrodes, or separate perpendicular layers form an X-Y grid that detects capacitance changes when touched.

Benefits of Capacitive Touch Screens

Capacitive touch screens can identify and measure multi-touch locations simultaneously. These touchscreens are more durable than resistive touchscreens, especially when subjected to heavy use. To operate a capacitive touchscreen, you just need to drag your finger across the surface. Minor cracks do not affect the operation of a capacitive touchscreen. A capacitive touch screen offers more clarity than resistive touch screens. It offers amazing image quality because of the usage of a glass layer.

Drawbacks of Capacitive Touch Screens

Capacitive touchscreens are more expensive than resistive touch screens. The price tends to rise exponentially with an increase in display size. These screens consume more power than resistive touch screens. Proper static charge interference is required to register a touch on capacitive screens. Hence only selective input objects such as bare fingers can interact with these screens.

How to Select Touch Screen

Several factors must be considered when choosing between capacitive vs resistive touch screens:

-

Budget: Resistive options tend to be more cost-effective.

-

Purpose: For multi-touch needs or high clarity displays, capacitive may be better.

-

Input Objects: If gloves or styluses will be used frequently, resistive is preferable.

-

Environment: For harsh or outdoor conditions with water/dust exposure, resistive has higher resistance.

-

Display Clarity: Capacitive offers superior optical performance.

-

Usage Time: Capacitive often lasts longer under frequent use.

-

Power Requirements: Resistive consumes less power.

-

Size Requirements: Capacitives can scale up beyond 28 inches more easily.

Comparison of Resistive vs Capacitive Touch Screens

| Feature | Resistive Touch Screen | Capacitive Touch Screen |

|---|---|---|

| Technology | Resistive | Electrostatic |

| Transmissivity | <82% | >90% |

| Touch Input | Any object | Conductive object |

| Waterproof | Good | Good |

| Stability | High | Normal |

| Response Time | <10 ms | <15 ms |

| Intense Light Resistance | Good | Poor |

| Multi-Touch Support | Limited | Excellent |

| Cost | Low | High |

| Screen Life | Good | Better |

| Accuracy & Resolution | Very High | Normal |

Each type offers different durability and sensitivity, making them suitable for specific industrial scenarios.

custom Capacitive and Resistive Touch Screens in Industrial Automation from Kadi Display

Kadi Display provides tailored solutions for both capacitive and resistive touchscreen technologies in industrial environments. Kadi Display offerings include:

We made the Cover Glass as your request. LOGO/Color/Shape/Thickness…

Customize FPC and Cable

Customize housing for easier assembly

Most of our high-brightness displays can reach over 800cd/m², or some even go up to 2500cd/m²

Optical bonding improves readability by eliminating air gaps between display layers

Their professional R&D team supports complete integration including LCM/TP/BONDING solutions—ideal for unique industrial automation needs.

FAQ

Q1: Which touchscreen works better outdoors?

That’s why resistive touch screens are still preferred over capacitive touchscreens in outdoor environments, due to their better resistance against moisture and accidental touches.

Q2: Can I use gloves with both types?

No. These screens do not require a conductive item like capacitive touchscreens. Only resistive types allow gloved operation.

Q3: Are all Kadi Display products customizable?

Yes. We made Cover Glass as your request… Customize housing for easier assembly, ensuring compatibility with varied industrial applications.

Q4: Which one lasts longer under frequent use?

Capacitives generally have better longevity due to their durable glass construction. However, if exposed to physical stress or sharp objects regularly, resistives may be easier and cheaper to replace.

Q5: Can I get large-size displays using resistives?

Not easily. Resistive touch technology is hard to build in sizes larger than 27 – 28 inches due to difficulties making uniform ITO coatings.

Latest Blog & News

- A Step-by-Step Guide to Mastering MIPI DSI

- Choosing the Best Display for Your Embedded Device

- Learn About the Industrial LCD Display Screen Size and Aspect Ratio

- Sunlight Readable Displays – the Most Important Parameters of Outdoor LCD Displays You Need to Know

- Stretched Bar LCD Displays Guide: Cost, Installation & Key Benefits