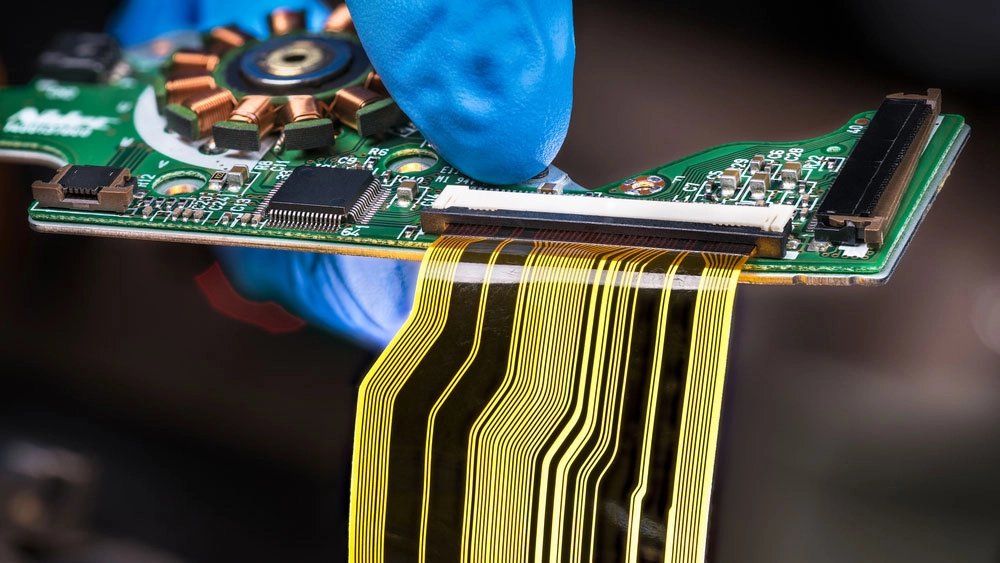

FFCs: Flat Flexible Cables

Types of FFCs

Flat Flexible Cables (FFCs) come in two main kinds. They depend on how the pins are placed.

- Type A (Same Side): This is the most common FFC. Pins line up on the same side at both ends. It’s also called Type 1 or Type BD.

- Type D (Opposite Side): One end has pins on top. The other has pins on the bottom. This is for special setups where devices have different pin layouts.

Parts of an FFC

FFCs have a few key pieces:

- Wires: Flat paths that carry electric signals between gadgets.

- Pins: Metal points at each end. They connect to device pins.

- Pitch: The gap between pins. It decides if connectors will fit.

- Support Tape: Extra layers at the ends. They keep the cable strong during plugging.

What FFCs are Made of

FFCs use flat copper wires. The ends are coated with tin. A bendy polyester layer wraps them for safety. Thick polyester stiffeners at the ends add support.

How FFCs Work

FFCs make a direct link between devices. Each pin on one end matches a pin on the other. Electric signals flow through these paths. This lets devices talk or share power.

Advantages of FFCs

FFCs bend easily. They’re great for things that move a lot. They’re cheap and simple to set up. Their easy design makes them useful for many projects.

Disadvantages of FFCs

FFCs are too simple for fancy circuits. They also might not last in tough places compared to other cables.

Common Uses of FFCs

FFCs are in cameras, robots, and gadgets like laptops or printers. You’ll find them in car dashboards, medical tools, and factory machines. They’re bendy and affordable, so they fit lots of jobs.

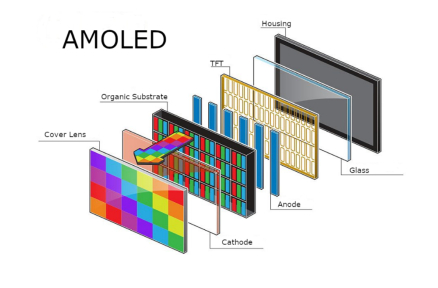

FPCs: Flexible Printed Circuits

Parts of an FPC

FPCs have more complex parts than FFCs:

- Pins: Metal contacts for hooking up devices.

- Pin Out: The setup that makes sure signals line up right.

- Pitch: The space between pins. It checks connector fit.

- Through-Holes: Coated holes that link layers.

- Electrical Traces: Paths carved into the base for signals.

- Electrical Components: Built-in parts like resistors or capacitors.

- Stiffener: Hard spots for extra strength.

- Substrate: The bendy base that holds the circuit.

What FPCs are Made of

FPCs use polyimide or polyester as their bendy base. Copper traces stick to it with glue. Multi-layer FPCs have copper-coated through-holes for connections. A polyimide cover protects against dust or weather.

How FPCs Work

FPCs connect devices like FFCs. Pins at each end carry signals. But their inner traces handle trickier signal paths. In multi-layer FPCs, signals jump between layers through holes.

Advantages of FPCs

FPCs are great for complex circuits. Their multi-layer design fits special jobs. They’re tough in harsh places. They stay bendy even with fancy setups.

Disadvantages of FPCs

FPCs cost more because they’re harder to make. Their specific designs make them less reusable for different projects.

Common Uses of FPCs

FPCs are in smartwatches, phones, and car systems like ADAS. They’re used in medical tools, plane navigation, and factory robots.

Differences Between FFCs and FPCs

The big difference is complexity. FFCs have simple wires for basic links. FPCs have fancy circuit designs. They’re like tiny, bendy PCBs.

FFC vs FPC vs Rigid Cable Comparison Table

Here’s how Flat Flexible Cables (FFCs), Flexible Printed Circuits (FPCs), and rigid cables stack up:

|

Feature |

FFC |

FPC |

Rigid Cable |

|

Complexity of Functions |

Low |

High |

High |

|

Customization |

Low |

High |

Low |

|

Thickness |

Very thin |

Thin (varies) |

Thick |

|

Overall Size |

Small |

Small (varies) |

Large |

|

Weight |

Light |

Light |

Heavy |

|

Durability |

Okay |

High |

Varies |

|

Cost |

Low |

Medium |

High |

|

Common Uses |

Gadgets, robots, wearables |

Factory tech, energy systems |

Tough, lasting connections |

|

Advantages |

Easy, cheap |

Bendy, complex |

Strong, lasting |

|

Disadvantages |

Simple functions |

Costs more |

Big, stiff |

Choosing Between an FFC and FPC

Picking between an FFC and FPC means knowing what your project needs. Both cables have special perks for different jobs.

Complexity of Functions

FFCs are perfect for simple links. They don’t need fancy routing or complex circuits. They give direct 1:1 connections. FPCs handle trickier circuits. They can have multiple layers and extra parts. This makes them great for phones or driver-assist car systems.

Movement

If your project needs lots of bending, both FFCs and FPCs work. FFCs are awesome for simple flexing in robots or gadgets. FPCs shine in tight spots. They bend into weird shapes while keeping circuits working.

Budget

FFCs are cheaper. Their simple design saves money. They’re great for tight budgets. FPCs cost more. Their fancy materials and making process raise the price. But they’re worth it for complex needs.

Environmental Conditions

FFCs do okay in mild heat. For tough spots with high heat or chemicals, FPCs are better. Their strong design and materials like polyimide hold up.

Space Constraints

FFCs are great for small spaces with simple paths. But for tiny spots needing complex routing or layered circuits, FPCs are the way to go.

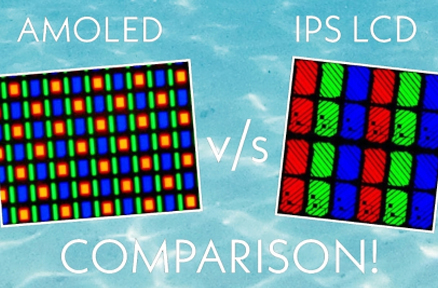

Best China Display Manufacturer: Kadi Display

Kadi Display is a top name in China’s screen industry. They have over 20 years of know-how. Kadi doesn’t just make TFT-LCD screens. They offer full display solutions for all kinds of needs.

Their factory covers over 5,000 square meters. It has top gear for LCM/TP/BONDING work. Their R&D team builds things like signal adapter boards and aluminum cases. This ensures high-quality products. They meet tough standards like ISO9001, IATF16949, and ISO13485.

Kadi Display offers lots of custom options:

- Cover glass with your logo, color, shape, or thickness.

- Tweaking backlight brightness or thickness.

- Changing LCM and CTP pinouts.

- Offering interfaces like TTL, LVDS, MIPI, EDP, HDMI, or Type-C.

- Building custom cases for easy setup.

They focus on quality with strict AOI checks during TFT LCD bonding. This keeps displays working great. Kadi’s IPS TFT LCDs show awesome colors. They have wide viewing angles up to 178 degrees. They stay clear in bright light with high brightness over 800cd/m².

Kadi Display goes beyond making screens. They make each product special. They cut development time for clients. Using Shenzhen’s supply chain, Kadi delivers fast, custom solutions for your projects.

For those needing flexible cables in advanced screens or standalone solutions, Kadi Display is a trusty partner. They bring new ideas and top quality to the world market.

Frequently Asked Questions About FFCs and FPCs

What’s the main difference between FFCs and FPCs?

FFCs are simple. They use flat wires for basic connections. FPCs are complex. They have circuit designs like tiny, bendy PCBs.

When should I use an FFC?

Use FFCs for easy, cheap connections. They’re great for gadgets, robots, or wearables that don’t need fancy circuits.

When is an FPC better?

FPCs are best for complex jobs. Think phones, car systems, or medical tools. They handle multi-layer circuits and tough conditions.

Are FFCs or FPCs more durable?

FPCs are tougher. Their materials like polyimide stand up to heat and chemicals. FFCs are okay but less strong in harsh spots.

Why choose Kadi Display for flexible cable solutions?

Kadi offers custom, high-quality displays with flexible cables. Their 20 years of experience and strict checks ensure great products. They’re fast and reliable.

Latest Blog & News

- A Step-by-Step Guide to Mastering MIPI DSI

- Choosing the Best Display for Your Embedded Device

- Learn About the Industrial LCD Display Screen Size and Aspect Ratio

- Sunlight Readable Displays – the Most Important Parameters of Outdoor LCD Displays You Need to Know

- Stretched Bar LCD Displays Guide: Cost, Installation & Key Benefits