Understanding LCD Display Driver Board Noise Issues

What Causes Noise in LCD Driver Boards?

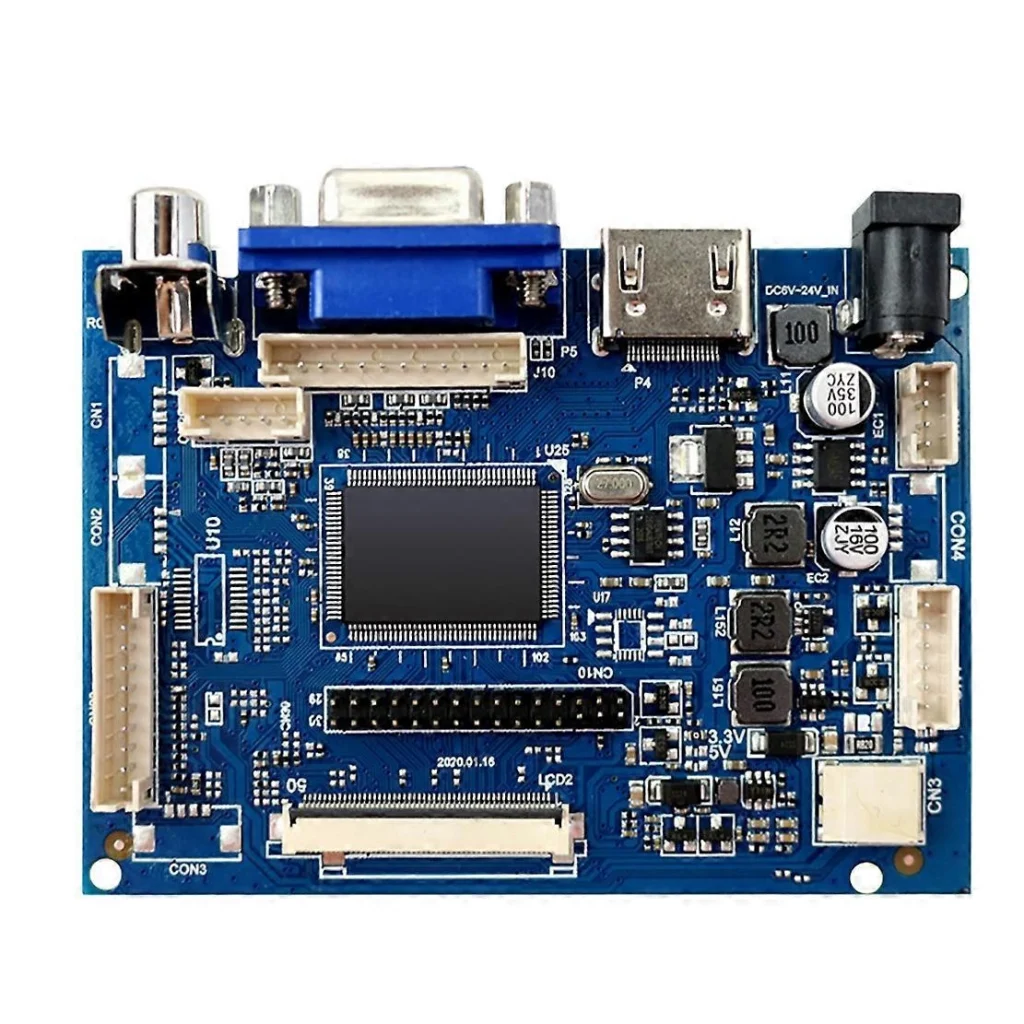

Noise in an LCD display driver board can be frustrating. It’s often caused by a few key problems. One of the most common reasons is the PWM (Pulse Width Modulation) frequency. If it’s set within the audible range—usually below 20 kHz—it can make a high-pitched buzzing or whining sound.

Another big cause is electromagnetic interference, or EMI. When circuits aren’t well-shielded, signals can interfere with each other. This can lead to strange noises, especially in a compact or poorly designed driver board for an LCD screen. Sometimes, it’s even loose components, like inductors or transformers, that vibrate and make noise. Poor grounding can also create ground loops, which result in hums or static sounds.

Voltage issues play a part too. Fluctuations in voltage can affect how stable the driver board works. Old or aging capacitors often cause this problem. If they’re dried out or swollen, they won’t filter noise properly, and the whole LCD screen driver board could suffer.

Why Should You Address Driver Board Noise?

Ignoring noise issues in an LCD touch screen driver board can be risky. For starters, that annoying buzz or whine can reduce display quality. It might make images flicker or reduce brightness control accuracy. That’s especially bad for touch screen monitor driver boards, where both visuals and touch input need to be reliable.

Constant noise can also cause user discomfort, especially in quiet environments. Over time, that can be a serious problem in places like hospitals, offices, or home theaters.

Even more, noise is often a sign of something wrong inside the circuit. If left unchecked, it could lead to component failure. Fixing it early helps keep your screen driver board working smoothly for a long time.

Step-by-Step Solutions to Fix LCD Driver Board Noise

Step 1 – Locate the Noise Source

Before fixing anything, you need to find where the noise is coming from. Try using a simple stethoscope or even a rolled-up piece of paper to listen to each part of the board. Inductors and transformers are the usual troublemakers. Try loading the board with more current and see if the noise changes. This helps confirm which part is acting up.

Step 2 – Check Power Supply & Filter Circuits

Next, look at the power supply and filter parts. Bad capacitors are a common issue. If you see bulging or leaking ones, replace them right away. You can also add small ceramic capacitors to help with high-frequency filtering. Use an oscilloscope to check if the voltage coming out of the power supply is smooth and steady. A noisy or fluctuating supply can easily affect an LCD display driver controller board.

Step 3 – Optimize PWM Frequency & Signal Quality

Many driver boards use PWM to control brightness or touch response. If the frequency is too low, it can cause audible noise. Try setting it above 20 kHz—this usually puts it out of human hearing range. If that’s not enough, reduce signal interference with snubber circuits or add small buffer resistors to smooth out spikes in current.

Step 4 – Secure Inductors & Transformers

Sometimes the problem is mechanical. If parts like inductors or transformers are loose, they vibrate and make noise. Apply epoxy resin or rubber pads to keep them from moving. If they’re poorly designed or too small for your application, consider replacing them with better ones. This step is critical in a high-performance LCD touch screen driver board.

Step 5 – Improve Circuit Layout & Grounding

Finally, take a close look at how the board is designed. If high-frequency circuits are too close to analog parts, they can create interference. Try to separate them and keep high-current paths short. Use single-point grounding to avoid ground loops that cause hum or static. A well-designed touch screen driver board should always follow these best layout practices.

Advanced Troubleshooting for Persistent Noise

When to Replace Components

Sometimes, even after all the basic checks, the noise won’t go away. That usually means you’ve got a faulty part. Look for signs like burn marks, weird smells, or parts that get too hot. Try replacing suspicious components like capacitors or inductors and test the board again. This is especially important if you’re working with a custom lcd display driver board that may have rare or specific components.

Software-Based Noise Reduction Techniques

Not all noise comes from hardware. Software can also play a role. If your driver board supports firmware updates, try adjusting PID (Proportional-Integral-Derivative) settings. These can smooth control signals and reduce buzzing. For motor-driven screens, changing the dead-time settings can help reduce sharp switching noise.

Preventing Noise in LCD Display Driver Boards

Best Practices for Circuit Design

The best way to deal with noise is to prevent it during design. Always use high-quality EMI filters and shielded cables. These help block interference before it becomes a problem. Keep the layout compact and neat, especially on a touch screen driver board where space is tight and performance is critical.

Regular Maintenance Tips

Don’t forget regular upkeep. Dust can clog cooling fans and make parts overheat, which increases the chance of noise. Also, check solder joints now and then. If they crack or loosen, components can vibrate and buzz. Keeping your lcd display driver board clean and secure can save you lots of trouble later.

When to Seek Professional Help

Benefits of Customized LCD Driver Solutions

Sometimes, the best fix is to go custom. At Kadi Display, their customization service focuses on solving issues like noise at the design stage. With over 20 years of experience in TFT, OLED, and touchscreen integration, their team knows how to build quiet, efficient driver boards. Whether you need a touch screen monitor driver board or a driver board for lcd screen, they can craft one that meets your exact needs.

One customer had a screen that buzzed constantly. Kadi’s R&D team redesigned the driver board and completely eliminated the noise. The new lcd screen driver board not only worked silently but also improved display sharpness and touch sensitivity.

Why Choose Kadi Display?

Kadi Display operates a 5,000+ square meter factory in Shenzhen, offering rapid prototyping and mass production. They specialize in HDMI and DSI interfaces, Raspberry Pi-compatible displays, and embedded system solutions. Their engineering team can support everything from basic lcd display driver controller boards to advanced lcd touch screen driver board designs.

FAQs About LCD Display Driver Board Noise

Why does my LCD driver board make a buzzing sound?

It’s usually due to PWM frequency being in the audible range or loose components like inductors.

Can a faulty capacitor cause display noise?

Yes. Old capacitors can’t regulate voltage well and often cause instability and noise.

How do I test if my driver board’s grounding is faulty?

Use a multimeter to check for solid connections between ground points.

Is high-frequency noise harmful to my LCD screen?

Over time, yes. It can stress components and reduce the life of the screen.

Can software updates reduce driver board noise?

Definitely. Firmware adjustments can optimize signal control and reduce buzzing.

Take Action Against LCD Noise Today!

Get Expert Support from Kadi Display

If you’re tired of dealing with noise, reach out to the experts. Kadi Display can design a custom driver board tailored to your specific application. Whether it’s a touch screen monitor driver board or a compact screen driver board, they’ve got you covered.

Contact Kadi Display today at Sales@sz-kadi.com or +86-13662585086 for a free consultation.