HMI Defined

A Human-Machine Interface (HMI) is a screen or panel that lets a person talk to a machine, system, or tool. This term can mean any screen for using a device. But, it’s mostly used for factory work. HMIs are a bit like Graphical User Interfaces (GUI). Yet, they aren’t the same. GUIs often help HMIs show pictures or data clearly.

In factories, HMIs do many jobs. They show data with pictures. They track how long tasks take, spot patterns, and mark important points. They watch key goals, check what machines do, and more. For example, you might use your home’s air conditioner panel to set the coolness. In a factory, a worker uses an HMI to adjust a water tank’s heat or check if a pump is running.

Simple HMIs include screens built into machines, computer screens, or tablets. No matter their shape or name, their main job is to show how machines are working. They stop old ways like writing machine updates on paper or boards.

Who Uses HMI?

HMI tools are used by nearly all factories and many other businesses to work with machines and make tasks smoother. Places like energy, food making, building things, oil and gas, power plants, recycling, transport, and water cleaning use HMIs.

The people using HMIs most are workers who watch machines, experts who mix software and hardware, and builders of control systems. These folks rely on HMIs to check work, find problems fast, and see important data clearly.

Common Uses of HMI

HMIs talk to Programmable Logic Controllers (PLCs) and sensors to grab data for users to see. Based on how they’re used in factories, HMI screens can do easy tasks like watching machines. Or, they can handle big jobs like turning machines off or changing how fast they work.

A big plus of HMIs is showing all live data in one place. Workers can see key numbers on charts or panels. They can also handle alerts well. Plus, HMIs can work with SCADA (Supervisory Control and Data Acquisition), ERP (Enterprise Resource Planning), or MES (Manufacturing Execution Systems).

Before modern HMIs, workers had to walk around factories to check machines by hand. This led to mistakes from missing info or human errors. Now, PLCs send live updates to HMI screens. This cuts errors and makes work more exact.

What is the Difference Between HMI and SCADA?

Supervisory Control and Data Acquisition (SCADA) systems are close cousins to HMIs. But, they do different things in factory controls. Both help automate tasks. Yet, HMIs mainly show info clearly so users can watch processes well.

SCADA systems, though, can collect tons of data from many places. They also control systems fully. Unlike SCADA, HMIs don’t save data or link to databases. Instead, they act as talk tools that work with SCADA systems.

Developing Trends in HMI Technology

High-Performance HMIs

Workers now lean toward high-performance HMIs. This design style makes fast, clear use easy. It puts the most vital signs front and center. This helps users spot and fix issues quickly. By showing data in a simple, neat way, these HMIs cut distractions. They help make smart choices fast. Signs on these HMIs are plain and free of extra pictures or buttons. Smart use of color, size, and spot boosts the user’s ease.

Touch Screens and Mobile Devices

Touch screens and mobile tools are new HMI types, thanks to smartphones. These let workers tap or touch screens to use systems, instead of old buttons or switches. Touch screens shine when paired with mobile HMI tools. Mobile HMIs give workers quick access to data and let them watch systems from afar.

Mobile tools with HMI features offer freedom and ease. They let users check controls and see data from almost anywhere. This is great when live watching or tweaks are needed, but being at the factory isn’t possible.

Remote Monitoring

Mobile-friendly remote watching gives workers and bosses more freedom. With this, engineers can check work from far away using small devices. For example, an engineer off-site can check a warehouse’s state or watch gear work without being there.

Using remote watching cuts the need for on-site checks, especially after hours. Soon, peeking at your factory’s work from miles away will feel normal.

Edge-of-Network and Cloud HMIs

Edge-of-network HMIs are popular too. They let workers grab data and pictures from field tools. These systems allow control nearby while handling data fast at network edges. Also, many businesses now use cloud-based HMIs to bring tasks together.

By sending data from local HMIs to cloud systems, companies can grow easier and access data from afar. Control stays local for safety, but cloud links allow deep checks across many sites or places.

Peering into the Future of HMI

Looking ahead, top builders are testing Augmented Reality (AR) and Virtual Reality (VR) to show factory tasks. These cool tools could change factory work by giving workers easier screens to use.

As factories rely more on live data, HMI tools will keep growing to meet needs. This tech has come far, but its growth has no clear end.

Partner with Kadi Display for HMI Displays

Kadi Display focuses on custom display answers for many factory needs. With over 20 years in the display world, they found many customers want more than a TFT-LCD. They need full display setups with touch, PCBA, and cases.

Kadi Display owns a factory over 5,000 square meters that makes LCM/TP/BONDING parts on its own. Their skilled R&D team builds signal adapter boards, single-chip boards, and parts like aluminum or metal cases. Also, Kadi Display uses Shenzhen’s strong supply chain to give customers quick display answers.

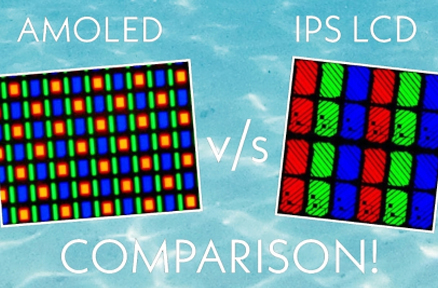

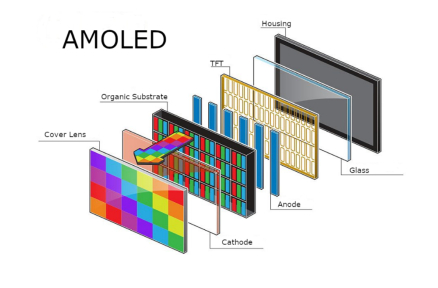

Kadi Display’s skills include IPS TFT LCDs with wide views up to 178 degrees. These screens show bright colors and stay strong in many settings. Whether you need optical bonding or custom links like HDMI or USB-C, Kadi Display offers unique answers that make products stand out and cut building time. Contact Kadi Display today!

FAQ

What industries benefit most from using HMI displays?

Places like energy making, food processing, building goods, oil and gas work, power plants, recycling, transport, and water cleaning use HMIs a lot.

What are some examples where modernized HMI improves efficiency?

Examples include touch-screen controls replacing old switches or mobile HMIs letting workers watch systems from afar.

Latest Blog & News

- IPS vs Other Panels How to Select Display Interfaces for Embedded and Industrial TFT LCD

- 7-Inch MIPI DSI Displays: Top Specifications and Best Choices in 2026

- Wide Temperature TFT Displays for Industrial Applications

- Display Coatings How AG, AF, and AR Solutions Solve Critical Display Problems

- A Step-by-Step Guide to Mastering MIPI DSI