Clear visibility is super important. Whether you’re building tough outdoor kiosks or precise diagnostic devices, bright light can turn a clear screen into a shiny mirror. That’s where anti-glare (AG) and anti-reflective (AR) coatings come in handy. They help keep your screen easy to see.

Anti-Glare vs. Anti-Reflective Coatings—The Basics

Both anti-glare and anti-reflective coatings fight the same problem: light reflection. But to understand how they’re different, we need to know what reflection is and how these coatings handle it.

What is Reflection and How to Reduce It?

Reflection happens when light bounces off a surface, like the glass on your LCD or TFT display. Based on the Fresnel equations, regular glass reflects about 4-5% of light per side. In a typical setup—air to glass, glass to display, and back—that adds up to 8-10% total reflection. Picture 10,000 lux of bright light, like sunlight or a busy warehouse. That 4.5% reflection could ruin your contrast ratio, dropping it from a sharp 400:1 to a hard-to-read 4-5:1. The human eye needs at least a 5:1 contrast to see clearly. So, reflections aren’t just annoying—they can be risky in serious places like factories or hospitals.

You can’t stop reflection completely (physics sets limits). But you can reduce its effect. AG and AR coatings are built to keep your screen’s content clear, even in tough lighting.

Differences Between Anti-Glare and Anti-Reflective Coatings

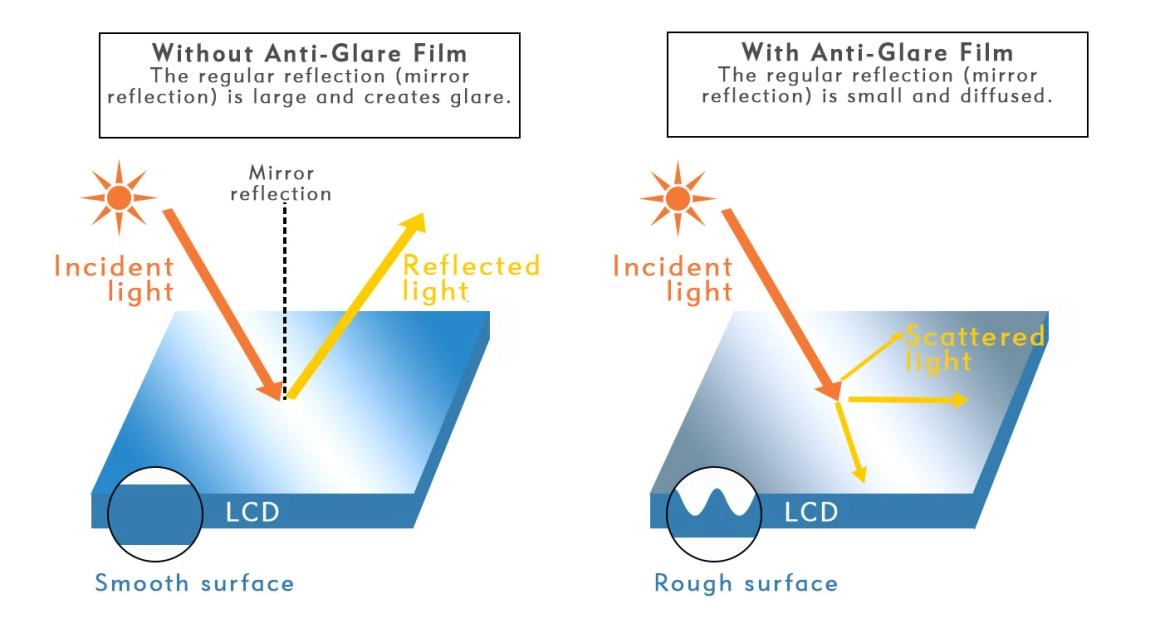

The big difference between anti-glare and anti-reflective is how they work. Anti-glare coatings scatter reflected light, spreading it out so it doesn’t create a bright, distracting glare. This makes reflections less noticeable, but the amount of reflected light stays about the same.

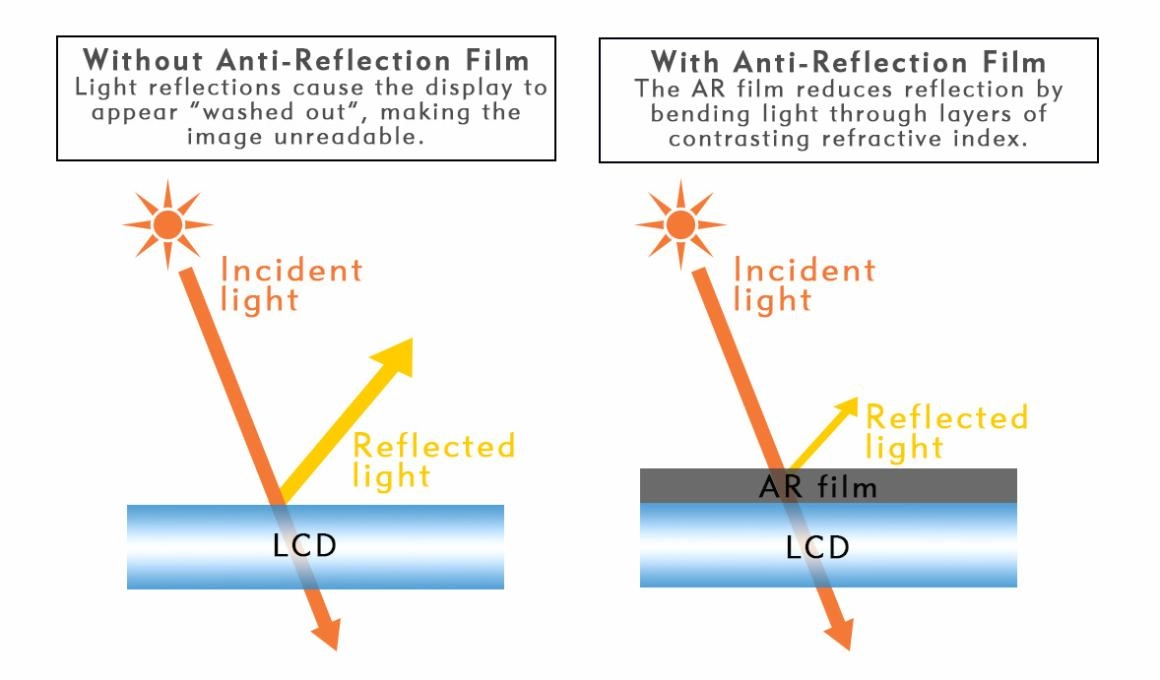

Anti-reflective coatings take a stronger approach. They cut down the actual light reflected by using destructive interference. Thin layers of materials with different refractive indices are placed on the glass. These layers make incoming light waves cancel out their reflections. This can lower reflectance to under 0.5% while letting over 99% of light pass through.

Think of AG as frosting a window to blur what’s outside. AR is like tinting it to stop light from bouncing back. For B2B buyers choosing displays for factories or medical tools, this difference affects things like edge-to-center contrast ratios (ECR) and upkeep over time.

Anti-Glare Coating—How It Works, Pros & Cons

Anti-glare coatings have been used in screen making for years. They’re loved for their simple use and wide compatibility. But how do they do their job?

How Anti-Glare Coatings Work

AG treatments etch or add tiny textures—like mini pyramids or beads—onto the glass surface. These textures are super small, about 0.1 to 1 micron. This roughness turns mirror-like reflections into scattered ones, spreading light in all directions. From where you’re looking, the reflection seems dimmer because only a few scattered rays reach your eyes. It’s a clever trick: your brain sees the scattered light as less bright, making the screen easier to read without changing how much light is reflected.

This is done with chemical etching for glass or adding silica particles for films. It works on LCD, TFT, OLED, and even bendy surfaces.

Pros of Anti-Glare Coatings

-

Budget-Friendly Making: AG costs 30-50% less than AR. It’s simpler to make, not needing vacuum chambers or strict controls. It’s great for big B2B orders like point-of-sale terminals or public kiosks.

-

Flexible Use: Works on many materials, like plastics and films. It pairs well with touch overlays or polarizers. It’s perfect for mild outdoor use, like digital signs in shaded spots.

-

Fast Production: Quick processes mean shorter wait times. This keeps B2B projects on track and within budget.

In factories, AG is awesome where budgets are tight but clear viewing is needed—like monitors on factory floors.

Cons of Anti-Glare Coatings

-

Slightly Blurry Images: The scattering haze can soften images, especially on high-resolution screens (>300 PPI). Colors may look faded, and tiny details—like text in medical charts—might blur, affecting precise tasks.

-

Cleaning Challenges: Textured surfaces catch dust, fingerprints, and smudges more easily. This makes cleaning harder. In clean places like hospitals or food factories, this could cause contamination risks.

-

Limited Glare Control: AG reduces direct glare well but doesn’t improve contrast in super bright light (>20,000 lux). Reflections can still lower ECR.

For business folks, these trade-offs make AG best for affordable, mid-level uses. It’s not ideal for top-notch, high-clarity needs.

Anti-Reflective Coating—How It Works, Pros & Cons

If AG is the trusty workhorse, AR is the precise expert—offering top performance at a higher price. Its smart design comes from tech used in camera lenses and aerospace.

How Anti-Reflective Coatings Work

AR coatings use multiple layers of materials—like magnesium fluoride or silicon dioxide—added through sputtering or evaporation in a vacuum. Each layer’s thickness (quarter-wavelength for specific light colors) and refractive index are set so reflections from the top (air-coating) and bottom (coating-glass) cancel each other out. Blue light? One layer. Full visible light? More layers for broader coverage.

The result: reflectance drops to 0.2-0.5%, with nearly perfect light pass-through. Paired with optical bonding (removing air gaps), AR can push outdoor ECR past 15:1, even in bright sun.

Pros of Anti-Reflective Coatings

-

Awesome Image Quality: No haze means sharp resolution, bright colors, and full PPI. It’s perfect for medical imaging where every pixel matters or factory HMI panels needing clear visuals.

-

Better Readability: Real reflection reduction shines in tough lighting, from operating rooms to EV charging stations. High light pass-through saves backlight power, helping battery life in portable devices.

-

Tough and Easy to Clean: Smooth surfaces resist scratches (with hard coats) and wipe clean easily. This suits high-touch B2B settings like public kiosks or car dashboards.

In business, AR’s benefits make it worth the cost for critical displays where poor visibility can’t be risked.

Cons of Anti-Reflective Coatings

-

Higher Price: Complex making raises costs, especially for custom multi-layer designs. B2B budgets need to balance this with performance gains.

-

Tricky Production: Needs cleanrooms and precise control, leading to longer wait times and less flexibility for unusual materials.

-

Limited Light Range: Single-layer AR targets specific light colors. Broadband versions cost more without being perfect for all light.

Even with these challenges, AR’s perks often beat the downsides in tough fields like aerospace or medicine.

Comparison and Applications

Picking between AG and AR depends on your project’s needs. It’s not a one-size-fits-all choice. Let’s compare them directly.

Impact on Image Quality and Readability

| Aspect | Anti-Glare (AG) | Anti-Reflective (AR) |

|---|---|---|

| Reflection Reduction | Scatters light (perceived, ~4-8% reflectance) | Cancels light (actual, <0.5% reflectance) |

| Image Sharpness | Some softening; haze factor 1-5% | None; full resolution kept |

| Contrast Ratio (ECR) | Improves to 8-10:1 in bright light | Boosts to 15:1+ with bonding |

| Best For | Budget displays, moderate lighting | High-res, extreme environments |

AG fits consumer gadgets or indoor factory controls, where a bit of haze is okay. AR is best for medical screens (like ultrasound displays) or high-PPI factory monitors (>300 PPI), avoiding pattern issues from rough textures. For outdoor B2B uses like solar-powered signs, AR’s efficiency prevents washout.

Costs and Recommendations for Different Projects

AG’s lower cost ($5-10 per sq. ft. vs. AR’s $15-30) appeals to big producers. But AR pays off with fewer errors and longer life. Suggestions:

-

Budget Projects: AG for retail POS or warehouse tablets—reliable without going overboard.

-

High-Stakes Needs: AR for medical diagnostics, car HUDs, or military gear, where clarity saves lives.

-

Mixed Needs: Pair with bright backlights (>1000 nits) for best results.

Consider compatibility: AG works well with flame-retardant glass; AR shines with bonded stacks. Always test prototypes in real lighting to check ECR.

In short, AG scatters light for good performance, while AR cancels it for top precision. For B2B innovators, picking the right coating makes your product go from okay to amazing.

Frequently Asked Questions (FAQ)

Which coating is better for outdoor industrial displays?

Anti-reflective is better for bright sunlight, giving higher contrast and no haze, though it costs more. Anti-glare works for shaded or mild outdoor use.

Do these coatings affect touch functionality?

Both work with capacitive touch. But anti-glare’s texture might add slight friction. Anti-reflective keeps touch smoother.

How much does anti-glare vs. anti-reflective add to display costs?

Anti-glare adds 30-50% less cost than anti-reflective, depending on scale and specs—great for budget B2B projects.

Partner with Kadi Display: Elevate Your Display Solutions Today

Ready to add top-notch anti-glare or anti-reflective coatings to your factory or medical displays? Kadi Display Technology Co., Ltd., a leading Shenzhen-based maker with over 20 years of know-how, offers tailored TFT LCD, OLED, and touch-enabled solutions. We meet ISO9001, ISO14001, ISO13485, and IATF16949 standards.

In 2023, we helped over 2,000 customers with 100+ custom projects. We provide one-stop services from design help to full production. Whether you need bright panels with AR for surgical clarity or budget-friendly AG for tough kiosks, our team offers fast prototyping and smooth integration.

Contact us now for a free consult: Visit www.kadidisplay.com or email Sales@sz-kadi.com to talk specs. Let’s build displays that shine in any light—quote your project today!

Latest Blog & News

- IPS vs Other Panels How to Select Display Interfaces for Embedded and Industrial TFT LCD

- 7-Inch MIPI DSI Displays: Top Specifications and Best Choices in 2026

- Wide Temperature TFT Displays for Industrial Applications

- Display Coatings How AG, AF, and AR Solutions Solve Critical Display Problems

- A Step-by-Step Guide to Mastering MIPI DSI