Het achtergrondverlichtingssysteem speelt een grote rol in hoe een display eruit ziet en hoeveel vermogen het gebruikt. Als een belangrijk onderdeel van LCD'shet heeft een sterke invloed op beeldhelderheid, energieverbruik en de slankheid van het apparaat. Laten’ Neem een nadere kijkje naar zes populaire achtergrondverlichtingstypen - CCFL, WLED, ELED, DLED, Mini LED en PWM - om meer te weten te komen over hun basisprincipes, voordelen en toepassingen.

CCFL

Basisprincipes van koude kathode fluorescerende lampen

De vroege achtergrondverlichting keuze was CCFL, of koude kathode fluorescerende lampen buizen. Deze lijken veel op oude-school fluorescerende lampen. Ze werken door kwikdamp te stimuleren om ultraviolette stralen af te geven, die vervolgens een speciale coating in de buis laten gloeien met zichtbaar licht.

Structuur en componenten van CCFL-achtergrondverlichting

CCFL valt onder buisvormige lichtbronnen. Het vereist een lastige opstelling van diffuserplaten en optische films om licht gelijkmatig over het scherm te verspreiden. Naarmate schermen groter worden, zijn er meer CCFL-buizen nodig, waardoor het ontwerp moeilijker te beheren is.

Voordelen en beperkingen van CCFL-technologie

CCFL biedt een heldere, koele toon en fatsoenlijke kleuren display. Maar het komt met veel nadelen. Het is niet erg efficiënt, verbruikt meer energie, dekt slechts een klein kleurenbereik (tot 72% NTSC), heeft een dikkere constructie nodig vanwege de buisgrootte en maakt zorgen over het milieu vanwege kwik in de binnenkant.

Toepassingen en markttrends voor CCFL-displays

Vanwege het hoge energieverbruik en de schade aan het milieu is CCFL tegenwoordig vrijwel verdwenen. Het was vroeger gebruikelijk in oudere LCD-schermen en tv's, maar nu zijn LED-opties volledig overgenomen.

WLED

Hoe witte LED-achtergrondverlichting werkt

WLED staat voor White Light Emitting Diode. Deze LED's gebruiken blauwe chips met een gele coating of een mix van rood, groen en blauw om wit licht te creëren. Dit licht verspreidt zich gelijkmatig over LCD-schermen.

Belangrijkste kenmerken en voordelen van WLED-oplossingen

In vergelijking met CCFL is WLED een enorme stap vooruit. Het is nu de topkeuze voor de meeste LCD-scherm achtergrondverlichting. WLED biedt betere energiebesparing, slankere vormen, snellere respons, langere levensduur en het is vriendelijker voor de planeet omdat er geen kwik bij betrokken is.

Efficiëntie en kleurnauwkeurigheid in WLED-displays

WLED's zorgen voor een betere controle van de helderheid terwijl ze minder energie gebruiken. Ze kunnen een breed scala aan kleuren verwerken, waardoor ze geweldig zijn voor gadgets zoals telefoons en tablets die een echt kleurendisplay nodig hebben.

Gebruiksgevallen en industrie adoptie van WLED

WLED's regeren vandaag de dag de markt voor gadgets. Van laptops tot tv's en zelfs industriële schermen zoals die van Kadi Display, die geweldige kleuren en solide energiebesparingen bieden, zijn WLED's de go-to voor zowel dagelijkse als topschermbehoeften.

ELED

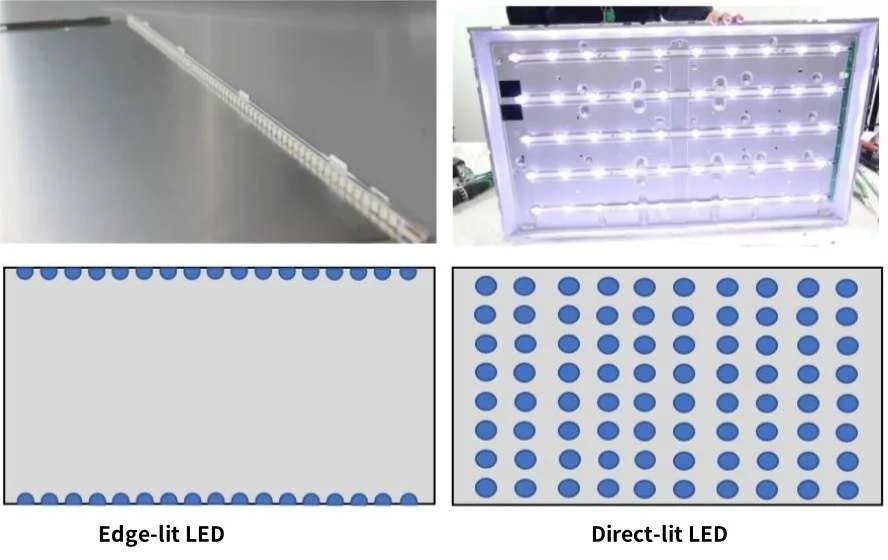

Begrijp Edge-Lit LED-technologie

ELED betekent randverlichte LED. Hier zitten LED's langs de zijkanten van het scherm. Een speciale plaat leidt het licht om het hele oppervlak gelijkmatig te bedekken.

Ontwerp Kenmerken van ELED Panelen

Deze instelling helpt superdunne schermen te creëren omdat minder LED's rond het frame nodig zijn in vergelijking met het bedekken van de hele achterkant. Daarom werkt ELED goed voor slanke items zoals ultrabooks of tv's die aan muren zijn gemonteerd.

Prestatievergelijking met andere LED-technologieën

Hoewel ELED-schermen dunner zijn dan DLED-schermen, moeten bedrijven extra inspanningen doen om helderheid en beeldkwaliteit te beheren. Als het niet goed wordt gedaan, kan dit ongelijk licht of zwakker contrast veroorzaken.

Typische toepassingen voor ELED-displays

ELED verschijnt vaak in TV's en monitors van midden niveau waar een slanke uitstraling belangrijker is dan schitterende contrastfuncties. Je zult het ook zien in betaalbare signage voor bedrijven.

DLED

Fundamenten van Direct-Lit LED-achtergrondverlichting

DLED staat voor direct-lit LED. In deze stijl worden LED's gelijkmatig achter het scherm geplaatst. Hierdoor schijnt de achtergrondverlichting gelijkmatig over het hele scherm.

Verschil tussen DLED en ELED

In tegenstelling tot randverlichte installaties heeft DLED LED's direct achter het scherm. Dit maakt het paneel dikker, maar maakt een betere lokale dimming mogelijk voor scherpere contrastniveaus.

Helderheid en uniformiteit in DLED-schermen

DLED-schermen zorgen voor constante helderheid over grote gebieden. Ze hanteren de controle van achtergrondverlichting en beeldkwaliteit vrij goed, waardoor ze een goede pasvorm zijn voor het tonen van HDR-inhoud.

Gemeenschappelijke toepassingen in consumentenelektronica

DLED is een favoriet voor high-end televisies waar heldere beelden een must zijn. Het wordt ook gebruikt in pro-grade monitoren, zoals die van Kadi Display, met helderheid van meer dan 1000nits voor buitengebruik of moeilijke industriële instellingen.

Mini LED's

Wat Mini LED onderscheidt van traditionele LEDs

Mini LED verwijst naar LED's met een kleine chipgrootte van 50-200μm. Deze kleine lichten laten fabrikanten duizenden in één scherm passen, in tegenstelling tot de honderden die in oudere ontwerpen worden gebruikt.

Technische specificaties en ontwerpoverwegingen

De zones kunnen springen van slechts een paar honderd naar duizenden of zelfs tienduizenden. Dit maakt het mogelijk om exact te dimmen in specifieke gebieden. Elke zone komt overeen met meerdere pixels, waardoor het dynamische bereik wordt verhoogd zonder helderheid te verliezen.

Voordelen in contrastverhouding en lokale dimmingszones

Met betere lokale dimming kunnen Mini LED achtergrondverlichting LCD's contrastverhoudingen boven 1.000.000:1 bereiken. Hierdoor kunnen ze concurreren met OLED-schermen, terwijl ze de burn-in-problemen die verbonden zijn aan organische materialen ontwijken.

Integratie in moderne displays

Mini-LED's verschijnen in fancy tablets, laptops en gaming-monitors en raken helderheidsniveaus tot 3000 nits of meer. Maar goedkopere Mini LED-schermen kunnen een halo-effect vertonen als de zones niet goed worden gecontroleerd.

PWM

De rol van pulsbreedtemodulatie in achtergrondverlichtingscontrole

Pulse Width Modulation, of PWM, maakt gebruik van besturingssignalen om de helderheid van een LED aan te passen. Het doet dit door het licht snel aan en uit te schakelen met verschillende snelheden, die het menselijk oog meestal niet kan opmerken.

Hoe PWM invloed heeft op helderheidsaanpassing en energieefficiëntie

PWM kan de helderheid van de achtergrondverlichting LED's op de vlucht veranderen op basis van wat er op het scherm staat. Deze slimme aanpassing bespaart energie tijdens donkere scènes en scherpt ook het contrast dat u ziet.

Potentiële problemen: flikkerperceptie en oogspanningsrisico's

Zelfs met zijn voordelen kan PWM een knippering veroorzaken bij lage snelheden, wat leidt tot vermoeidheid van de ogen of hoofdpijn voor sommige mensen. Het gebruik van hogere snelheden kan helpen om dit probleem veel te verminderen.

Beste praktijken voor de implementatie van PWM in displaysystemen

Voor de beste resultaten kan de lokale dimming worden verdeeld in 1D licht (randverlicht) of 2D licht (direct verlicht of Mini LED). Het 2D-type geeft de scherpste beelden, met contrastverhoudingen tot 500.000:1 wanneer het goed wordt gedaan met behulp van Mini of directe verlichte LED's.

Veelgestelde vragen

V: Welke achtergrondverlichtingstechnologie biedt het beste contrast?

A: Mini LED met 2D lokale dimming geeft het beste contrast, meer dan 1 miljoen: 1 wanneer correct ingesteld.

V: Wordt CCFL vandaag nog steeds gebruikt?

A: Nee, het is bijna verdwenen.

Wat is beter: ELED of DLED?

A: Het hangt af van het gebruik. ELED is slanker, terwijl DLED een betere controle biedt over de beeldkwaliteit.

Krijg uw display groothandel van Kadi Display: Beste China Display Monitor Factory

Kadi weergave biedt volledige oplossingen, waaronder TFT-LCD modules gekoppeld aan touchscreens (CTP), PCBA-platen en behuizingen. Ze bieden ook aangepaste opties zoals interface tweaks (LVDS / MIPI / HDMI) en optische binding met OCA / OCR-lijm voor taaiheid.

Wij maken Cover Glass aan uw behoeften - LOGO, kleur, vorm of dikte.

We passen FPC's, kabels, achtergrondverlichting, pinouts en behuizingen aan precies wat u wilt.

Voor betrouwbare IPS TFT-lcd's met hoge helderheid tot 2500cd/m² helderheid garandeert Kadi heldere zichtbaarheid in zonlicht en snelle reactietijden met AOI-gecontroleerde productie.

Bekijk ons brede assortiment, waaronder harde industriële modules zoals de "12.3" TFT-LCD Module met hoge helderheid". Neem vandaag nog contact op met ons deskundige team!

Laatste Blog & Nieuws

- Stretched Bar LCD Displays Guide: Cost, Installation & Key Benefits

- 7 Inch LCD Selection Guide: 800×480 to FHD | RGB/LVDS/MIPI DSI display | Kadi

- HDMI LCD Displays: How to Use Them and What Their Main Features Are

- What Is MIPI DSI (Display Serial Interface)?

- IPS vs TN – How to Choose the Right Display Technology?