Als touchscreen technologie Als het steeds meer voorkomt in de industriële, automobiel- en medische sectoren, is de behoefte aan duurzame en hoogwaardige displays belangrijker dan ooit. Een van de meest effectieve methoden om de prestaties van het scherm te verbeteren is optische binding. Dit geavanceerde proces verbetert niet alleen de beeldhelderheid en mechanische sterkte, maar zorgt ook voor betrouwbaarheid in veeleisende omgevingen.

Wat is optische binding?

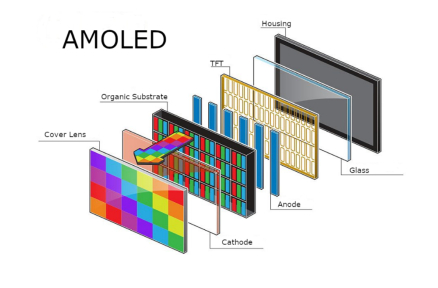

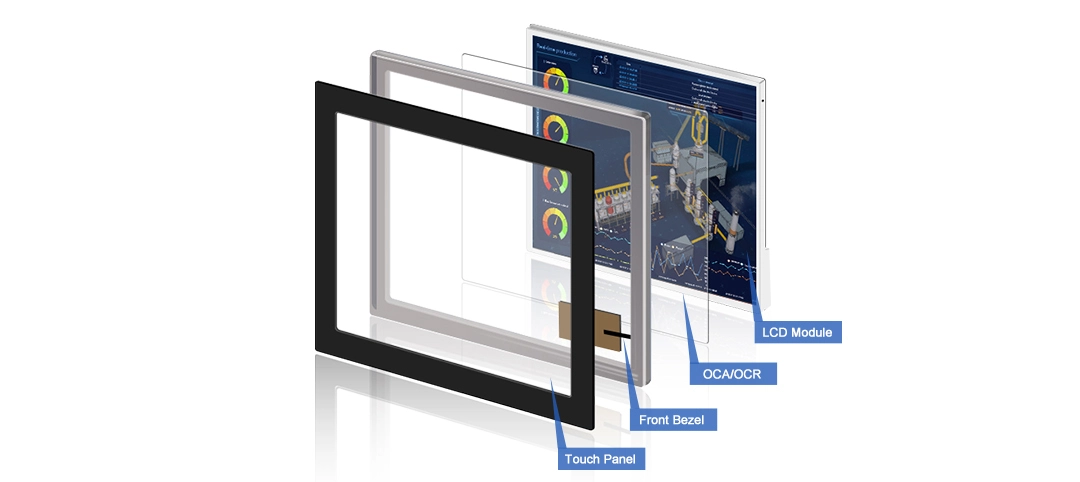

Optische binding dient om het display aan het touchpanel te binden. Dit proces vereist zorgvuldig geselecteerde lijm en unieke productietechnologie (meestal beschermd door octrooien of bedrijfsvertrouwelijkheid). Dit resulteert in hoogwaardige eindproducten met betere optische prestaties, duurzaamheid en andere voordelen zoals beschreven in het artikel.

Optisch bindingsproces

Voorbereiding

Het proces begint met het kiezen van het juiste type lijm, afhankelijk van de vereiste weergave parameters, zoals de grootte, de locatie van het apparaat (binnen of buiten) en geschatte werktemperaturen. In dit stadium moeten het display, het glas en het aanraakpaneel grondig worden gereinigd.

Lijminjectie

Dit omvat het nauwkeurig aanbrengen van lijm op het hele schermoppervlak. De specifieke lijmrecepten zijn strikt beschermd, hoewel er drie algemene soorten bindmaterialen zijn: siliconen, epoxyharsen, polyurethanen (nu verouderd vanwege het vergelen in de loop der tijd).

Bonding en behandeling

Dit is de cruciale stap van het hele proces omdat het aanraakpaneel wordt toegepast op de LCD-module. Het vermijden van gaten en luchtbellen is hier het belangrijkste probleem. Vervolgens wordt de lijm behandeld met UV-licht, omdat de traditionele warmtebehandeling het risico op materiaalkrimp zou verhogen.

SOCA – alternatief optisch bindproces

Wat is SOCA bonding?

SOCA (Solid / Silicone Optically Clear Adhesive) omvat het gebruik van een doorschijnende gel die onder hoge druk wordt gelamineerd in de vorm van kleefplaten. Hiervoor worden hoogwaardige siliconenmengsels gebruikt, die vervolgens dienen als een binding tussen het beschermglas, de sensoren van het aanraakpaneel en het LCD-scherm.

Optisch bindproces met SOCA

Het optische bindproces in de SOCA-methode lijkt op laminatie. Het gaat om het leggen van tweezijdige gelplaten, afgestemd op de grootte van de beeldschermcomponenten, die vervolgens aan beide zijden vacuüm worden gebonden.

Voordelen van SOCA optische binding

Bij deze technologie is UV-uitharding niet nodig, waardoor het risico op het gelen van het materiaal wordt verminderd. In vergelijking met het hierboven beschreven standaard "natte" proces is de SOCA-methode gemakkelijker te implementeren en behoudt de lijm een grotere flexibiliteit, waardoor het mura-effect wordt vermijden. Belangrijk is dat het binden met behulp van SOCA-gels omkeerbaar is en componenten opnieuw kunnen worden gebonden, wat eventuele reparaties en wijzigingen vergemakkelijkt, waardoor de onderhoudskosten van het apparaat worden verlaagd. De optische bindingstechnologie van SOCA heeft een positieve invloed op de kwaliteit van het weergegeven beeld.

Hoe beïnvloedt optische binding de weergave kwaliteit?

Verbeterde weergave kwaliteit - verminderde lichtweerspiegelingen en verbeterd contrast

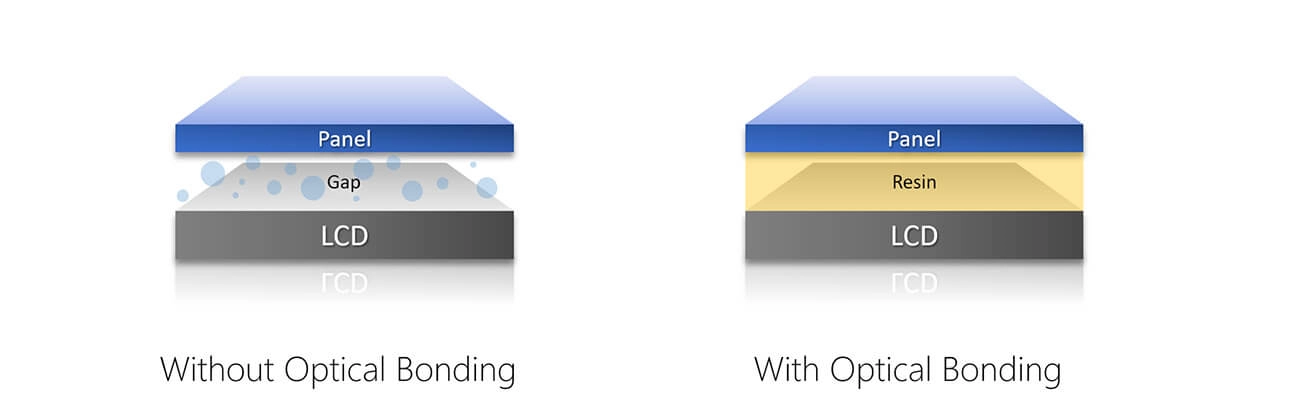

De optische bindingsmethode elimineert de luchtkloof tussen het beschermglas, de aanraaksensor en het scherm, waardoor de kwaliteit en leesbaarheid van het weergegeven beeld aanzienlijk worden verbeterd. Het is vooral zichtbaar in omgevingen met veel zonlicht (bijvoorbeeld buitentoepassingen) of sterk kunstmatig licht (bijvoorbeeld in verlichte productiezalen of operatiekamers van ziekenhuizen).

Het belangrijkste doel van het optische bindingsproces is het contrastverhouding van het scherm te verhogen door de hoeveelheid gereflecteerd omgevingslicht te verminderen.

Verminderde nadelen van Air Bonding

Een fundamenteel alternatief voor optische binding is luchtbinding Dit betekent dat bij luchtbinding er een luchtgap tussen lagen is Het resultaat van het gebruik van luchtbinding is verminderd contrast en leesbaarheid van het display.

Bovendien waar de aanrakingsfunctie mogelijk niet correct werkt vanwege gebrek aan een juiste aanrakingsgevoeligheid (ghost effect genoemd).

Condensatievermindering en stofbescherming

Vochtigheid en verontreinigingen kunnen gapen tussen schermlagen doordringen De ruimte gevuld met optische lijm elimineert dit probleem

Verhoogde mechanische duurzaamheid

Het verwijderen van luchtgap met optische lijm verhoogt de fysieke duurzaamheid Voldoet bijvoorbeeld aan de regels van IK7-norm die bescherming bieden tegen mechanische botsingen met energie 2J.

Uitgebreide temperatuurbereik en EMI-filtering

Het gebruik van optische binding betekent extra verbeteringen zoals een breder werktemperatuurbereik Om elektromagnetische interferentie te verminderen, kunnen EMI-filters aanvullend worden toegepast met behulp van ITO-technologie

Optische binding - risico's van onjuiste implementatie

Mura-effect

Vervormingen als gevolg van materiaalspanningen in lijm kunnen leiden tot mechanische schade die vooral zichtbaar is bij het weergeven van donkere inhoud Een zorgvuldig geselecteerd lijmmateriaal en een geleidelijk uithardingsproces dragen bij aan het verminderen van spanningen

Delaminatie – lijmkrimping

Krimping als gevolg van onjuiste uitharding bij te hoge temperaturen kan delamination veroorzaken Thermische tests hebben aangetoond dat dit verschijnsel bij 85 ° C afwezig is.

Lijfstof Geling

Geling kan zich na verloop van tijd voordoen als gevolg van UV-straling of blootstelling aan hoge temperaturen Om dit probleem te voorkomen raden we UV-bestande lijmen aan, rekening houdend met de vereisten voor de toepassing van de eindgebruiker

Waar wordt optische binding het beste gebruikt?

Optische binding wordt populair in verschillende toepassingen waar strenge omgevingsomstandigheden zoals een breed temperatuurbereik of directe zonlicht leesbaarheid vereist zijn.

Toepassingen omvatten:

-

Medische elektronische apparaten

-

Militaire apparatuur

-

Industriële machines & HMI's

-

Auto displays zoals die gebruikt in Tesla voertuigen

Deze sectoren eisen uitzonderlijke betrouwbaarheid en visuele prestaties - criteria die optische binding tot een ideale oplossing maken.

koop uw beste touchscreens van Kadi Display: neem contact met ons op voor het beste aanbod

Kadi weergave biedt een uitgebreid assortiment aangepaste TFT-LCD modules geïntegreerd met capacitieve of resistieve touchpanelen. Wij zijn gespecialiseerd in het leveren van volledig gebonden oplossingen met behulp van geavanceerde technieken, waaronder OCR / OCA voor verbeterde duurzaamheid.

Onze fabriek strekt zich uit over 5.000 vierkante meter waar we onafhankelijk LCM/TP/BONDING modules produceren. Onze R& D team ontwikkelt signaaladapterplaten en structurele onderdelen op maat voor uw behoeften.

Wij bieden:

-

Aangepaste dekglas (LOGO/Kleur/Vorm/Dikte)

-

Verstelbare achtergrondverlichting helderheid

-

Interfaceopties: TTL/LVDS/MIPI/EDP/HDMI/Type-C/VGA

-

Hoge helderheid tot 2500cd/m²

-

Volledige AOI-inspectie tijdens FOG-productie

Bijvoorbeeld:

10.1 "TFT LCD-scherm met optische binding & amp; anti-glare

12.1 "LVDS 1280 × 800 Hoge helderheid met CTP

7 inch Automotive TFT-LCD met optische binding

Onze displays zijn ontworpen voor uitstekende kleurreproductie, brede kijkhoeken tot 178°, snelle reactietijden en superieure duurzaamheid - zelfs onder zware omstandigheden.

Neem vandaag nog contact op met ons ervaren team voor technisch advies of aangepaste offerte. Laat ons u helpen een betrouwbaar product te bouwen dat wordt aangedreven door geavanceerde visuele technologieën.

Laatste Blog & Nieuws

- Een stap-voor-stap gids voor het beheersen van MIPI DSI

- Het beste scherm kiezen voor uw embedded apparaat

- Lees meer over de schermgrootte en aspect ratio van het industriële LCD-scherm

- Zonlicht leesbare schermen - de belangrijkste parameters van buiten LCD-schermen die u moet weten

- Gerekte Bar LCD Displays Gids: Kosten, Installatie & Belangrijkste voordelen