AMOLED (Active Matrix Organic Light-Emitting Diode) schermen staan als een topkeuze in display tech. Elke pixel creëert zijn eigen licht met behulp van organisch materiaal. Deze zelfverlichtingsmethode slaat de behoefte aan achtergrondverlichting die in oude LCD's wordt gevonden over. Het geeft echt diepe zwarten, eindeloze contrastniveaus en een betere energiebesparing. De actieve matrix setup maakt gebruik van thin-film transistors (TFT's) om elke pixel precies te verwerken. Het maakt snelle refresh snelheden en minder energieverbruik mogelijk. Deze functies maken AMOLED-schermen belangrijk in high-end telefoons, slimme horloges, dashboards voor auto's en VR-headsets. Ze bieden heldere kleuren en dunne constructies.

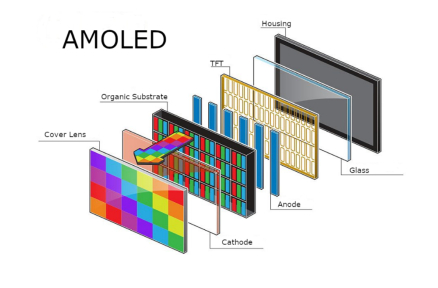

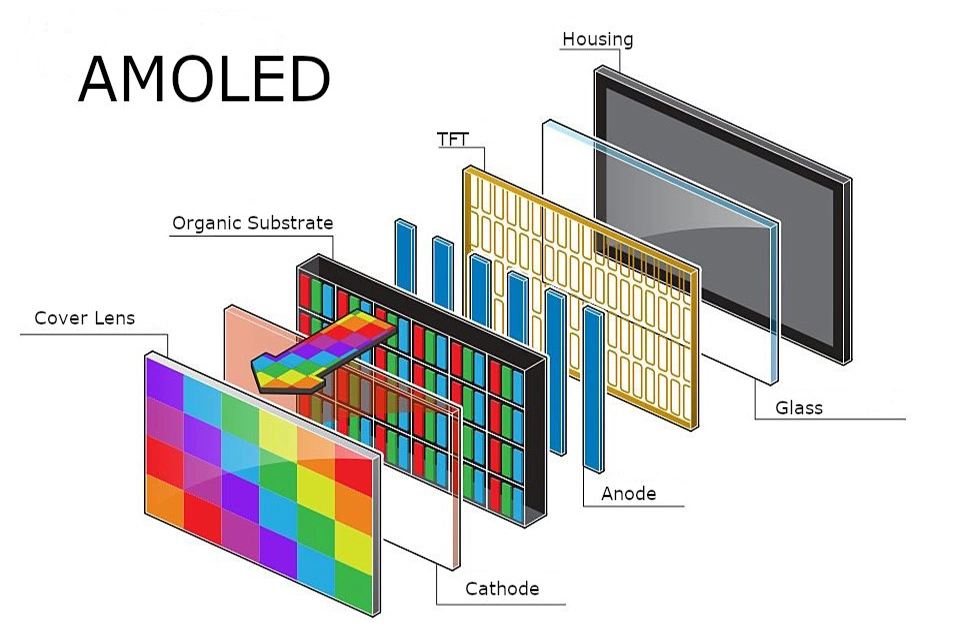

Wat bepaalt de structuur van een AMOLED display?

De bouw van een AMOLED-scherm wordt zorgvuldig gepland in vele lagen voor goed werk en kracht. Het belangrijkste onderdeel is het TFT backplane. Deze laag is vaak afkomstig van laagtemperatuur polykristallijn silicium (LTPS) of amorf silicium (a-Si). Het helpt elektronen snel te bewegen - LTPS-typen lopen tot 100 keer sneller dan a-Si-typen. Boven zit de anodelaag. Daarna komt de organische emissieve laag. Hier worden rode, groene en blauwe subpixels gemengd om alle kleuren te maken.

Kernlagen van AMOLED Display Architectuur

De kathodelaag voltooit het elektrische pad. De encapsulatielaag houdt de zachte organische delen veilig tegen luchtproblemen zoals zuurstof en water. Een polarisator zit bovenaan. Het verhoogt het zien door het snijden van glans. Bij buigbare AMOLED-soorten kan een speciale thin-film encapsulation (TFE) gebogen worden zonder te breken. Dit helpt opvouwbare gadgets en gebogen auto schermen.

Materialen die worden gebruikt in AMOLED TFT Backplane

De keuze van materialen maakt veel uit: organische polymeren in de lichtvormende laag, zoals gloeiende of schijnende kleurstoffen, bepalen kleurhelderheid en levensduur. Blauwe subpixels falen vaak eerst vanwege zwakke dingen. Ze hebben extra versterking nodig om burn-in te stoppen.

Hoe Subpixel-regeling invloed heeft op kleurnauwkeurigheid

Een scherp AMOLED-paneel in een 6,5-inch telefoon kan bijvoorbeeld meer dan 12 miljoen pixels hebben die alleen werken. Het verbruikt ongeveer 40% minder energie dan soortgelijke LCD's bij het tonen van donkere scènes. Gelijkheid in de TFT-laag is van vitaal belang. Oneven delen kunnen strepenfouten veroorzaken. Dit toont de noodzaak voor exacte maken methoden.

| Laag | Functie | Materiaal |

|---|---|---|

| TFT achtergrond | Pixel schakelen | LTPS/a-Si |

| Anode | Elektroneninjectie | geleidende metalen |

| Organische emissieve laag | Lichtemissie | organische polymeren |

| kathode | Recombinatie van gaten | Transparante geleiders |

| Encapsulatie | Milieubescherming | Glas met dunne film |

| polarisator | Glare Reductie | Polymeerfilmen |

AMOLED-pixeldichtheid en energieefficiëntie in echte apparaten

Dit laagplan hanteert niet alleen hoge pixels - vaak meer dan 500 pixels per inch (PPI) - maar past ook bij aanraakdelen en sensoren. Het opent toepassingen in fabriek en gezondheidsapparatuur.

Hoe werkt AMOLED pixelverlichting?

Pixelverlichting in AMOLED-schermen hangt af van elektroluminescentie. Dit is wanneer de elektrische stroom organische stoffen roert om licht te maken. Wanneer stroom raakt - meestal 2,7 tot 5 volt - gaan elektronen van de kathode in de emissieve laag. Ze verbinden zich met gaten van de anode. Deze energieuitbarsting verandert in fotonen. Golflengths krijgen ingesteld door de subpixel’ s organische mix: rode emitters rond 620-630 nm, groen bij 515-530 nm en blauw bij 445-460 nm.

Elektroluminescentieproces in AMOLED-subpixels

In tegenstelling tot LCD's die een constante achtergrondverlichting nodig hebben die door vloeibare kristallen wordt geleid, schakelt AMOLED alleen de benodigde pixels aan. Dit geeft echte controle per pixel. Het leidt tot contrastniveaus boven 1.000.000:1 en responstijden onder 0,1 milliseconden. Deze pak bewegende spullen zoals games of AR lagen.

Spanningsvereisten voor AMOLED Pixel-activering

Helderheid bereikt vaak 100-300 candela per vierkante meter (cd/m²). Het kan schalen tot 1.000 nits of meer in top auto panelen.

Rol van PWM Dimming bij het verminderen van schermflicker

Stabiliteit groeit met het toevoegen van iridiummenges of andere helpers. Dit verlengt de levensduur tot 15.000-30.000 uur. Dimming maakt gebruik van pulsbreedtemodulatie (PWM) bij snelheden boven 240 Hz om flikkers te verminderen. Maar lagere tarieven kunnen sommige mensen lastig maken.

Vergelijking van stroomverbruik: AMOLED vs LCD in videoafspelen

Energiebesparing valt op in dimme scènes. Een 6,1-inch AMOLED in video play trekt ongeveer 0,8 watt. Een LCD-match kost 1,2 watt. Maar witte schermen kunnen het gebruik met 60% verhogen. Dit wijst op het goede van donkere thema's.

Strategieën om de afbraak van blauwe subpixels te minimaliseren

Grijze interfaces maken het laden op blauwe subpixels gemakkelijk. Deze dragen het snelst. Het behoudt kleur zelfs in de loop van de tijd. Deze setup’ s slimme deel is zijn groeivermogen. Het gaat van kleine schermen in horloges tot grote schermen in borden. Precieze controle houdt het stabiele werk in verschillende lichten.

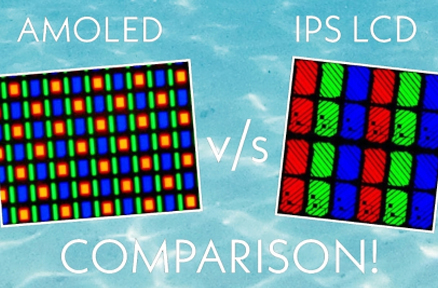

Welke voordelen hebben AMOLED's ten opzichte van LCD's?

AMOLED-schermen verslaan LCD's op veel belangrijke gebieden. Deze omvatten contrast, snelheid en vormopties. Geen achtergrondverlichting laat pixels volledig uitschakelen voor zwart. Het geeft eindeloos contrast in theorie - echte controles toppen vaak 1.000.000:1. Dit ver verslaat LCD’ s 1500:1.

AMOLED oneindige contrastverhouding uitgelegd

Reactietijden dalen tot 0,1 ms tegen 4-8 ms in LCD's. Het verwijdert bewegingssmear in snel gebruik zoals VR-games of auto-infosystemen.

Waarom AMOLED-responstijd LCD verslaat voor gaming en VR

Kleur maken treft 100% van het DCI-P3-assortiment met ingestelde organische emitters. Het overtreft goede LCD's met 98%. Buigen is een plus. AMOLED’ s dunne, lichte bouw maakt gebogen en opvouwbare vormen niet mogelijk met LCD’ s stijve achtergrondverlichting.

AMOLED kleuren versus LCD: DCI-P3 prestaties

Bekijk hoeken nabij 178 graden zonder kleurverandering. Stroomonderbrekingen - tot 40% in gemengde spullen - verlengen de batterij in handhelden.

Flexibele AMOLED-schermen in opvouwbare smartphones en wearables

Het maken van updates zoals Pentile subpixel plannen verlaagt de kosten met 18% met gedeelde onderdelen. Ze behouden de beeldkwaliteit. In auto's zorgen AMOLED-panelen voor dunnere randen en meer verpakte pasvormen. Ze werken 20% beter dan LCD's.

Energie-efficiëntie verhoogt met donkere modus op AMOLED-schermen

Deze sterke punten plaatsen AMOLED als de keuze voor diepe beelden. Dit gaat van gezondheidsfoto's die exacte tinten nodig hebben tot gebruikersgads die gemakkelijk dragen.

| Parameter | AMOLED | LCD-scherm |

|---|---|---|

| Contrastverhouding | 1,000,000:1 | 1,500:1 |

| Reactietijd | 0,1 ms | 8 ms |

| Flexibiliteit | Ja (Opvouwbaar) | Nee |

| Kleur Gamut | 100% DCI-P3 | Tot 98% |

| Stroomverbruik (donkere inhoud) | 40% minder | Basislijn |

Wat zijn AMOLED productie uitdagingen?

Het bouwen van AMOLED-schermen betekent het verslaan van grote obstakels. Deze variëren van zwakte spullen tot output verbetering. Organische lagen dragen snel - blauwe emitters drie keer sneller dan rood of groen. De kleuren kunnen na 5000 uur veranderen.

Blauwe Emitter Levensduur en Kleurverschuiving Problemen in AMOLED

Waterzwakheid vereist encapsulatie om toegang te blokkeren bij 10^-6 g/m²/dag. Het’ s als beschermen tegen droge extremen voor tien jaar.

Vereisten voor Thin-Film Encapsulation (TFE) voor vochtbescherming

Het neerzetten vereist vacuümkamers en schaduwmaskers met kleine nauwkeurigheid. Verkeerde plaatsingen mengen kleuren. De opbrengsten dalen met 15-20% onder de LCD's.

Precisie schaduwmaskertechnologie in AMOLED-productie

De overstap naar grotere Gen 8.5 substraten (2200×2500 mm) verlaagt de kosten. Maar het riskeert te buigen. Fixes omvatten laserverwarming voor 30% TFT evenheid winst en inkjet afdrukken voor grote patronen.

Laser annealing voor het verbeteren van LTPS TFT-uniformiteit

Gemengde manieren, zoals quantum-dot boosted OLED (QD-OLED), verhogen de helderheid tot 1500 nits. Ze versterken ook het leven. Inbranding van vaste onderdelen blijft een zorg. Het repareert met het bewegen van de pixel.

QD-OLED vs traditionele AMOLED: helderheid en levensduur vergelijking

UV-licht snelheden afbreken met 50%. Het vereist gecontroleerde plekken. Deze moeilijke delen stimuleren nieuwe ideeën. Ze geven panelen 99% uptime en 10.000 buigcycli voor buigbaar gebruik.

Kadi Display Expert Inzicht

Kadi Display, een fabrikant gevestigd in Shenzhen met meer dan 20 jaar in display-technologie, excelleert in AMOLED-oplossingen op maat voor de industriële en medische sector. Gebruikend partnerschappen met BOE, Tianma, Innolux en AUO, produceert het bedrijf modules van 7 tot 15,6 inch, met resoluties tot 3840× 2160 en helderheidsniveaus tot 600 nits. Aanbiedingen zoals de 14-inch 2880× 1800 eDP AMOLED (PN: KD140EWUHN) en 12,3-inch MIPI OLED met lens (PN: KD123EWUNN-FL) ondersteunen brede temperatuurbereiken (-30°C tot 85°C), ideaal voor automotive en ruige omgevingen. Gecertificeerd onder ISO9001, ISO14001, ISO13485 en IATF16949, Kadi’ s 10.000 ㎡ faciliteit maakt gebruik van geautomatiseerde TFT-lijnen voor aanpassing van hoog volume, geen MOQ, inclusief HDMI, MIPI en touch-integraties.

Veelgestelde vragen

Hebben AMOLED-schermen last van burn-in?

Ja, statische beelden gedurende langere periodes kunnen leiden tot ongelijke slijtage. Mitigatie omvat het verschuiven van pixels en het handhaven van helderheidsafwijkingen onder 2%.

Zijn AMOLED's beter voor de ogen dan LCD's?

AMOLED's verminderen de blauwe lichtemissie met 12% bij 450 nm en zorgen voor echte zwarten, die spanning verlichten. PWM dimming onder 500 Hz kan echter ongemak veroorzaken bij gevoelige personen.

Wat is de typische levensduur van een AMOLED-scherm?

De levensduur varieert van 15.000 tot 30.000 uur, beïnvloed door gebruik en materiaalstabiliteit, met verbeteringen die de betrouwbaarheid verlengen.

Hoe hanteren AMOLED-schermen hoge helderheid?

Ze bereiken tot 1.500 nits via verbeterde emitters, hoewel het stroomverbruik stijgt; optimalisaties zoals donkere modi balanseren prestaties.

Kunnen AMOLED's in industriële toepassingen worden gebruikt?

Absoluut, met robuuste encapsulatie en brede temperatuurtolerantie, passen ze bij zware omgevingen zoals machine-interfaces.

Partner met toonaangevende AMOLED-fabrikanten en -leveranciers voor aangepaste oplossingen

Kadi weergave staat als een toonaangevende AMOLED-fabrikant, leverancier en fabriek in Shenzhen, China, die sleutelbedrijfoplossingen levert voor B2B-partners wereldwijd. Met expertise in OEM/ODM-productie, geen minimale bestelhoeveelheden en snelle prototyping via geautomatiseerde lijnen maakt Kadi de naadloze integratie van hoogwaardige AMOLED-modules mogelijk in industriële, medische en automobielproducten. Neem contact op met het verkoopteam bij Sales@sz-kadi.com of 86-13662585086 om op maat gemaakte specificaties te bespreken, monsters aan te vragen of uw volgende project te starten - verhoog prototypes naar productie met Kadi’ gecertificeerde kwaliteit en efficiëntie van de supply chain.

Laatste Blog & Nieuws

- Een stap-voor-stap gids voor het beheersen van MIPI DSI

- Het beste scherm kiezen voor uw embedded apparaat

- Lees meer over de schermgrootte en aspect ratio van het industriële LCD-scherm

- Zonlicht leesbare schermen - de belangrijkste parameters van buiten LCD-schermen die u moet weten

- Gerekte Bar LCD Displays Gids: Kosten, Installatie & Belangrijkste voordelen