-

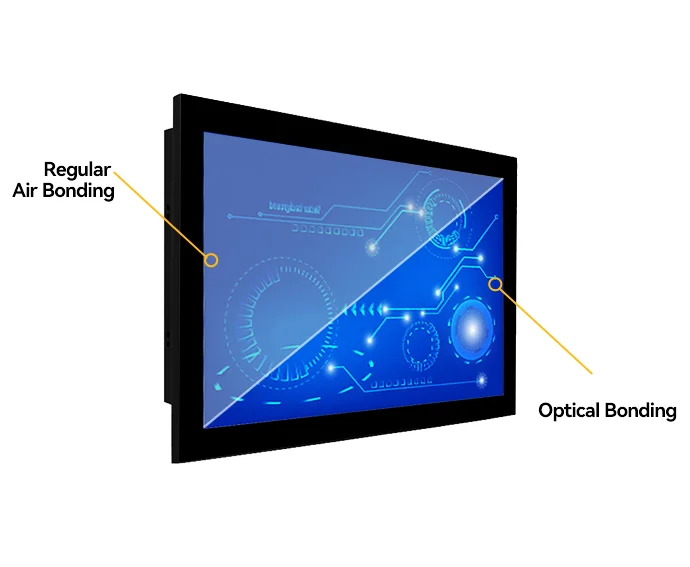

Optical Bonding

Optical bonding is a method that involves bonding TFT LCD and CTP using optical materials. This technique uses a transparent adhesive, such as Optically Clear Adhesive (OCA) or Optical Clear Resin (OCR) liquid optical adhesive, to bond the layers together, eliminating air gaps. This process improves the performance and readability of the display:

- Eliminating air gaps to reduce light reflection and scattering

- Prevent dust and moisture from entering the display

- Improve touch screen accuracy and sensitivity, reducing false touches and delays

- Enhancing the display’s performance to work steadily for a long time in harsh environments.

-

AOI For Quality Guarantee

-

AOI Inspection for Quality Assurance

To ensure long-term stability, we follow robust quality systems (ISO 9001 / IATF 16949 / ISO 13485) and strict process control. During the FOG bonding process, 100% AOI inspection is performed to verify alignment and electrical connection quality.

Our internal criteria require ≥5 conductive particles on the IC side and ≥10 conductive particles on the FPC side, helping reduce bonding-related risks and improving reliability for industrial and outdoor applications.

-

-

High brightness and optical bonding

High-brightness displays maintain content visibility in various lighting conditions, especially in strong outdoor light environments.

Most of our high-brightness displays can reach over 800cd/m², or some even go up to 2500cd/m².

- High contrast enhances image sharpness and detail richness.

- Sunlight readable

- High color reproduction

- Anti UV materials(Ceramic ink/anti UV SCA/OCA)

-

FAQ

Q1: Is this display readable in sunlight?

A: Yes. The module uses an 800 nits high-brightness backlight and is designed for outdoor and high ambient light environments to improve readability.

Q2: What interface does the LCD use?A: The LCD video interface is LVDS, suitable for many industrial embedded systems requiring stable transmission.

Q3: Does it include touch, and what touch interface is supported?A: Yes, it comes with CTP (capacitive touch panel). Touch interface supports I2C and USB depending on your system requirement.

Q4: What is optical bonding and why is it used?A: Optical bonding bonds the LCD and touch panel using optical adhesive to reduce internal reflections, improve sunlight readability, and help prevent dust/moisture ingress for better reliability.

Q5: What is the operating and storage temperature range?A: Operating temperature: -20°C to +70°C. Storage temperature: -30°C to +80°C.

Q6: Can you customize brightness, cover glass, or touch performance?A: Yes. We support customization for brightness/backlight, cover lens shape & thickness, AG/AR/AF surface treatment, and touch tuning (glove/wet touch/noise immunity).

Q7: Can you provide a datasheet and mechanical drawing?A: Yes. Please contact us to get the datasheet and outline/AA drawing for evaluation and integration.

Q8: What applications is this module suitable for?A: Typical applications include outdoor information terminals, industrial HMI, charging stations, parking systems, and other equipment that needs stable display performance in harsh environments.

| Item | Specification |

| LCD Size | 12.1 inch |

| Resolution | 1280×800 |

| Video Interface | LVDS |

| Brightness(cd/m²) | 800nits |

| Viewing Direction | Free view |

| Active Area | 260.35 (H) x162.72(V) |

| Pixel Pitch(mm) | 0.2034 (H) x 0.2034V) |

| Display Colors | 16.7M |

| TP Interface | I2C&USB |

| Outline Dimension(mm) | 312.12 (H) x 204.2 (V) x 8.71 (D) |

| Operating Temp | -20°C~70°C |

| Storage Temp | -30°C~80°C |

.jpg)