ما هو الترابط البصري؟

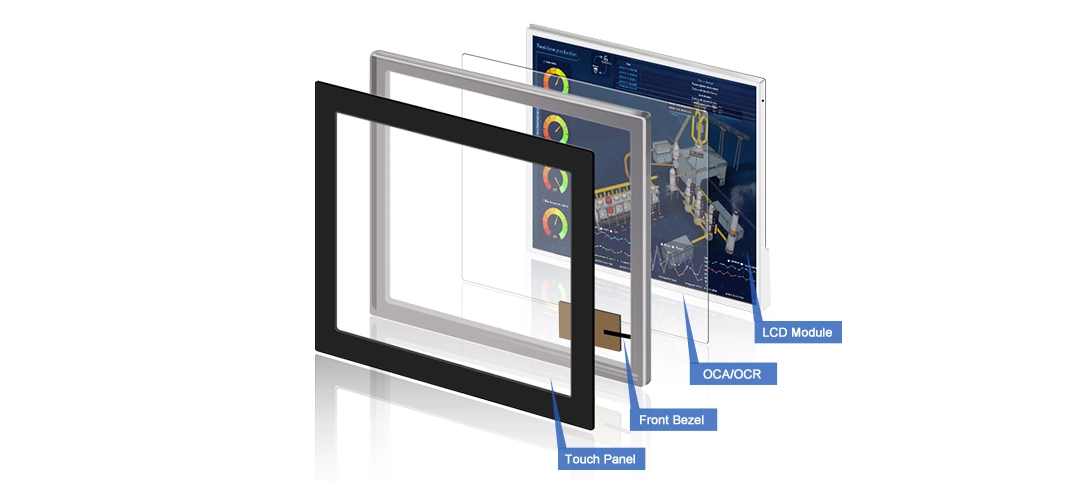

ربط بصري هو طريقة جديدة في تكنولوجيا الشاشة. إنه ينضم إلى جزئين خفيفين مع سحب صغير بينهما. يتخطى الغراء القديم مثل المعجون. في القلب ، يضع علكة خاصة بين شاشة اللمس وشاشة لوحة عرض كريستال سائل فيلم رقيق ترانزستور (TFT LCD). هذه الطريقة تغير الشاشات الصناعية كثيرا. يرفع رؤية من خلال، يجعل على الشاشة حادة، ويزيد من عمر المعدات الخاصة بك.

لماذا يحسب الارتباط البصري؟ في الأماكن القاسية ، مثل النباتات الغبارية ، أو الأماكن الخارجية الساخنة بالشمس ، أو غرف المرضى النظيفة ، غالبًا ما تفشل الشاشات العادية من اللامع أو الرطب أو الاهتزاز. الارتباط البصري يصلح هذه البقع الصلبة. إنه يجعل كومة خفيفة واحدة. هذا يقلل من خسارة الضوء والارتداد. للمحلات التي تصلح “ حلول العرض الصناعي ” يعني أقل أوقات التوقف ، وفواتير إصلاح صغيرة ، ومستخدمين سعداء. يقول خبراء في هذا المجال إن الشاشات المرتبطة ترفع قراءة بنسبة تصل إلى 40٪ في الشمس المستقيمة. وهذا يجعلهم مفتاحين للوظائف الصعبة.

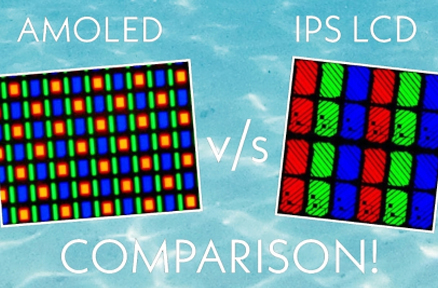

تخيل الأمر: أوراق الزجاج وأجزاء اللمس وشاشات LCD عالقة كشيء كامل. ترى هذا في الرسومات الشائعة “ طبقات من العناصر المرتبطة بصريا. ” هذا ليس مجرد حديث. إنها طريقة مؤكدة لتغيير الحقول التي تحتاج إلى شاشات قوية.

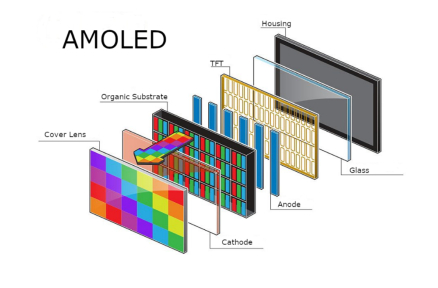

كيف يعمل الترابط البصري؟

يستخدم الارتباط البصري الغراء الخفيف لتلصق أجزاء الشاشة. لا يترك بقع هوائية. لذلك يذهب الضوء بسرعة من الضوء الخلفي إلى عينيك. الحيلة في الأشياء والخطوات. تتغير لتتناسب مع الاحتياجات. هناك ثلاثة أنواع رئيسية من الترابط البصري. الربط الرطب يستخدم الراتنج الواضح بصريا، أو OCR. يستخدم الربط الجاف أوراق لاصقة واضحة بصريا ، أو OCA. يستخدم ربط الفجوة الهوائية شريط الغراء لفجوة صغيرة.

كل طريق يبدأ في أماكن نظيفة بدون غبار. هذه غرف نظيفة إنهم يمنعون أجزاء سيئة من إصابة العصا. الهدف؟ قطع البقع حيث الضوء ينحني بشكل خاطئ. هذا يسبب ضبابية أو تحولات. للأشخاص الذين يسألون “ عملية الترابط البصري ” كل شيء يتعلق بالرعاية. وضعت الغراء. ثم تصف الأجزاء تحت الضغط. العلاج التالي لإبقاء كل شيء في مكانه. هذا يجعل الشاشات تبدو أكثر وضوحا. كما أنها تأخذ الطقس البري، من -40 درجة مئوية باردة إلى 85 درجة مئوية ساخنة.

ما هو OCR أو "الربط الرطب" ”؟

الراتنج الضوئي (OCR) ، أو “ الارتباط الرطب ” هو الطريقة القوية القديمة في ربط الحيل. هكذا سيكون الأمر. يتم خلط علكة واضحة ، وغالباً ما تكون الأسمنت البصري ، بعناية. يتم تنظيفها لتخطي كرات الهواء أو القمامة. هذه الأشياء الرطبة تذهب على وجه TFT LCD. ثم شاشة اللمس أو غطاء الزجاج يجلس على الجزء العلوي مباشرة.

العلاج يأتي بعد ذلك. يستخدم الأشعة فوق البنفسجية (UV) في معظم الأحيان. هذا يجسد اللثة في حوالي ساعة. هذا أسرع بكثير من طرق الحرارة القديمة التي استغرقت أيامًا. التنظيف بعد العلاج هو المفتاح. الطريق يمكن أن تجعل الفوضى. لكن الفوز هو انضمام سلس. إنه يعطي أعلى جودة رؤية ومقبضة قوية.

العلكة من السيليكون تقود منذ السبعينات لوظائف LCD. لماذا ؟ ينمو قليلا مع الحرارة. لذا لا انحناء في قفزات الحرارة. يتخطى المحادثات السيئة مع أشياء الشاشة. ويدفع الماء بعيدا. هذا يحارب التراكم الرطب. بالإضافة إلى ذلك ، فإنه ينحني في شكله. يبقى واضحا لفترة طويلة بدون تحول إلى الأصفر. وتبقى رخيصة.

ما هو OCA أو "التلاصق الجاف"؟

الآن إلى اللاصق الضوئي (OCA) ، أو “ رابط جاف. ” إنه عالم نظيف وسريع. OCA يستخدم أوراق مقطوعة من الأشياء الصلبة. هذا غالبا ما يكون السيليكون أو الأكريليك. لديها أغطية على جانبين لسهولة التمسك. لا رطوبة تعني لا تسرب أو كرات. لذلك فهي تناسب خطوط صنع السيارات.

الخطوات؟ سحب الغطاء. اربط الورقة بين الـ LCD والزجاج الغطائي. اضغط في صندوق حرارة. كل شيء ينتهي في أقل من 30 ثانية. يحدث هذا في غرفة نظيفة. هذا العمل السريع يعني المزيد للصناع الذين ينمو “ خدمات الربط البصري. ”

الارتباط الجاف يعمل بشكل جيد في وظائف الرعاية. انها ترفع واضحة وضربت عقد. لا علاج الألم من الطرق الرطبة. إنه الاختيار الأفضل لشاشات اللمس LCD TFT الجديدة. السرعة والتأكد من العمل يعود الدفع.

الرطب مقابل الجاف الترابط البصري

اختيار بين الربط البصري الرطب والجاف؟ إنه مثل اختيار بدلة مصنوعة (رطبة) أو تخزين واحدة قوية (جافة). الرطب يحتاج محترف الاستعداد لتخطي ثقوب الهواء. يريد معرفة عميقة للمزيج. وهو يلتصق إلى الأبد. لا إصلاح سهل. هذا يمكن أن يجلب القمامة أو الضرر. أوقات العمل تذهب طويلة من العلاج. لكنه يعطي أعلى سلس لمشاهد فائقة الوضوح.

الارتباط الجاف يحوله. التحولات السريعة، إصلاح السندات، والورقة الصلبة عقد تخطي الفوضى. انها تناسب السيارة. لديها معركة أفضل للضربات، والاهتزازات، والمؤقتات. وتتجاوز المخاطر الصفراء مع الأشياء قبل الصلبة.

ماذا عن ربط الفجوة الهوائية؟

ليس كل العصا تحتاج إلى أي فجوة. يستخدم ربط الفجوة الهوائية ، أو غراء الإطار ، حلقة حول جوانب الشاشة. يربط أجزاء خفيفة. يترك بقعة هواء رقيقة في الوسط. هو رخيص، لا علاج، وخفيف. يستخدم أشرطة متجر.

هذه الطريقة تناسب احتياجات صغيرة داخل الوظائف. لا لمع، رطب، أو البرية الحرارية. ولكن في أماكن التغيير ، مثل أرضيات القوارب أو لوحات الشمس ، تفتقر إلى ذلك. بقع الهواء تنمو ترتد وتبقى رطبة. لـ “ فجوة الهواء مقابل الترابط البصري” يبدو أن الأخير يفوز بقوة.

كيف يمكن للاتصال البصري الرطب أو الجاف تحسين الرؤية؟

انظر المشاكل تأتي من الانحناء: الضوء يتحول في الانضمامات بين الهواء والزجاج والأشياء الصلبة. ينشر الأشعة ويجعل لامعا. كثير من الأوراق؟ تنمو الصعب. ربط الفجوة الهوائية يجعل هذا أسوأ في الخارج. أضواء الشمس أو الرأس تغسل الشاشات.

الرطب والجاف الارتباط البصري ملء الفجوات مع المواد انحناء المباراة. الضوء يذهب مباشرة لصور واضحة. هذا يقلل من الارتدادات بنسبة 90٪ في بعض الأحيان. يرفع خطوط حادة. ويقوي ضد الضباب. الرسومات غالبا ما تظهر هذا. كومة عالقة مقابل فجوة واحدة تظهر اختلافات كبيرة في القراءة. بالنسبة للمحترفين في المصنع، يعني هذا العمل الآمن. الطيارون يرون تحذيرات في حفر القضيب. أو الدكتور يرى مسحات لا تجمع.

ما هي مزايا الترابط البصري الرطب والجاف؟

الماضي نرى، رطبة وجافة شاشة رفع الارتباط البصري قوية كثيرا. أهم الأشياء الجيدة هي:

-

أفضل قراءة في بقع الشمس العالية: الارتدادات الصغيرة تبقي الكلمات واضحة في الضوء الساخن. مفتاح لوحات الإشارات الخارجية.

-

رفع الصورة العمل: الأسود الداكنة والألوان الكاملة والبقع الواسعة تعطي مناظر عميقة لـ HMIs.

-

أكثر قوة وقوة: العصا تأخذ الضربات. فهي تحمي من السقوط أو الاهتزازات في مراكز الحركة.

-

أطول شيء الحياة: رطب مقاوم يقطع الصدأ. فإنه يصلح الفواتير الصغيرة على مر السنين.

-

أفضل شاشة تعمل باللمس: تجعل ورقة إضافة الشعور الحاد للمحادثات بدون عيب في المقاعد.

هذه الجيدة تجعل الارتباط البصري لا بد من “ شاشات صناعية قوية. ” يقلل من التكاليف الخاصة بنسبة 20-30%.

أمثلة على تطبيقات الربط البصري عبر الصناعات

ينمو الارتباط البصري حيث تستسلم الشاشات المعلقة بالهواء. في الطعام والمشروبات ، يستغرق الغسيل دون تقسيم. يبقي نظيفا، لا توقف جعل الخطوط. البقع المريضة والمخدرات تدفع الكيمياء والرطبة. يحمي البقع النظيفة من الصدأ.

تبقى الشاشات الخارجية ولوحات الإشارات مشرقة تحت الشمس القاسية. اقرأ من بعيد للناس الإعلان. الوقوف و HMIs في البيع أو المتجر تأخذ لمسات صعبة والطقس. محطات صغيرة. الجيش والقارب والجو والشحن والتحرك يعتمدون عليه لمناظر لا تلمع في الضربات والملح والعواصف. فكر في لوحات حفرة القضيب أو مسار التحميل.

من النباتات إلى خطوط القتال ، “ تطبيقات الترابط البصري” تغير الكثير. إنهم المفتاح.

الاتجاهات المتوقعة في تكنولوجيا العرض

مع تقدم الصناعة 4.0 بسرعة ، تتغير الشاشات من الأشياء الجانبية إلى مراكز الحديث. في الثلاجات الذكية، والعتاد على الهيكل، والسيارات الكهربائية، وأكثر من ذلك. وقت الشاشة يقفز. يحتاج العصا التي تضع المستخدم متعة وعقد أولا. الطقس يتحول، الصيف أصعب، الشتاء رطب، اختبار ينتهي. تنمو البيانات تدعو إلى انضمامات آمنة بدون تسرب.

لماذا تختار الشاشات المرتبطة بصريا من الشركات المصنعة الرائدة؟

الترابط البصري ليس فقط تقنية. إنه تغيير مؤكد. إنه يسلح الشاشات للأعمال الشاقة مع السحر الرطب والجاف. ولكن اختيار الفريق المناسب؟ المفتاح. هذا هو المكان الذي يجتمع فيه المعرفة.

في نهاية المطاف لدينا كيف على “ ما هو الترابط البصري ” فكر: هذه التكنولوجيا لا تتحدث. هو العمود الفقري للشاشات الصناعية القوية. من OCR’ s رطبة المهارة إلى OCA’ s سريع صعب، فإنه يضرب فجوات الهواء في كل مرة. إنه يعطي رؤية، قوية، وعودة الدفع أن الشاشات العادية يمكن’ ت ضرب. كما تدور نهايات الدفع ، ستحكم الإصلاحات المتعلقة. إنهم يحافظون على عملك الحاد والأمن.

أسئلة متكررة

س: ما’ الفرق بين الربط البصري الرطب والجاف؟ ج: الرطب (OCR) يستخدم الراتنج السائل المعالجة بواسطة الأشعة فوق البنفسجية للسندات السلسة ؛ جاف (OCA) يستخدم الأوراق الصلبة لتصفيق أسرع وأنظف. الجاف أسرع وأكثر قابلية لإعادة العمل، في حين أن الرطب يوفر تكامل متفوق.

س: كيف يحسن الترابط البصري رؤية العرض؟ ج: من خلال ملء الفجوات الهوائية ، يقلل من انكسار الضوء والانعكاسات ، ويعزز التباين والقراءة - خاصة في ظروف مشرقة أو رطبة.

س: ما هي المزايا الرئيسية للارتباط البصري على طرق الفجوة الهوائية؟ ج: إنه يعزز المتانة ، ويمدد عمر ، ويحاد الرسومات ، ويحسن استجابة اللمس ، ويقلل التكاليف على المدى الطويل.

مستعد لربط طريقك إلى شاشات صناعية متفوقة؟ شريك مع كادي ديسبلي اليوم

كشركة رائدة مقرها شنتشن مع أكثر من 20 عاما في الابتكار العرض، عرض كادي تصنع حلول ربط بصرية مخصصة لمرؤى B2B في المجالين الصناعي والطبي. لدينا 10,000 ㎡ المرفق ، بدعم من شهادات ISO9001 ، ISO14001 ، ISO13485 ، و IATF16949 ، يضخ شاشات TFT LCD ، وألواح لمس سعة ، وشاشات لمس TFT مخصصة مع الهواء أو ربط بصري كامل.

رفع عملياتك - انعكاسات تقطيع ، ومتانة ، ومستقبلية مع عملياتنا المستوحاة من VacuBond. اتصل بفريقنا الآن للاستشارة المجانية حول حلول TFT الترابط البصري المخصصة. زيارة kadidisplay.com أو البريد الإلكتروني Sales@sz-kadi.com لمناقشة مشروعك. دعونا’ ربط براعة في شاشاتك - الحافة تنتظرك!

آخر مدونة وأخبار

مدونة ذات صلة وأخبار

-

TN مقابل IPS2024-7-9

-

TN مقابل IPS2024-7-9