How Do Size and Resolution Impact Your Industrial Monitor Choice?

Evaluating Size and Format Requirements

When choosing an industrial display screen, for your setup’ it’s important to consider the size factor carefully’. The perfect size will guarantee a fit within the allocated area. Offer ample screen space for all your work needs. Take into account the surroundings where the screen will be placed and the duties it will undertake. Larger screens are great for tasks as they enable users to access data sources at once. On the other hand,’ smaller screens are better suited for spaces, with limited room availability’.

Assessing Resolution Needs for Clarity and Precision

When selecting an industrial monitor resolution becomes a consideration to keep in mind too. Having a high-resolution display can provide clarity and accuracy, for tasks that involve detailed visual analysis. In sectors like manufacturing or medical diagnostics where precision is key opting for a resolution screen can greatly enhance overall accuracy and productivity. Kadi Display offers a range of products such as the 8.0-inch TFT-LCD Module with CTP that cater to these needs.

Why Is Operating Temperature a Critical Factor?

Determining Suitable Temperature Ranges for Your Environment

Industrial environments often expose monitors to extreme temperatures, making it vital to select a monitor capable of operating within those conditions. Assess the typical temperature ranges in your workspace and choose a monitor designed to function reliably within those limits. Monitors like Kadi Display’s 10.1″ TFT LCD LVDS Interface are engineered to withstand diverse environmental conditions.

Ensuring Reliability in Extreme Conditions

Reliability under extreme conditions is non-negotiable for industrial monitors. Whether dealing with high heat or freezing temperatures, the monitor must maintain consistent performance without risk of failure. Opt for monitors that have been rigorously tested for durability in challenging environments.

Is Touch Input Necessary for Your Application?

Exploring Touchscreen Technologies

Touch input can enhance interactivity and efficiency in many industrial applications. Evaluate whether your operations would benefit from touchscreen capabilities, considering factors like ease of use and speed of interaction. Touchscreen technologies vary, so understanding their differences helps in making an informed decision.

Deciding Between Tactile or Non-Tactile Interfaces

Deciding between tactile (touch-enabled) and non-tactile interfaces depends on your specific application needs. Tactile interfaces offer direct interaction with on-screen elements, which can streamline processes in environments like control rooms or manufacturing floors.

What Are the Essential Connection Ports for Your Industrial Monitor?

Understanding Connection Port Options

The types of ports, on your monitor decide how well it can work with systems you have in place already. Some typical ports are HDMI connections for high-definition video and audio transmission DisplayPort for high-resolution display output, VGA for analog video signals, and USB interfaces, for connecting devices. Make sure the monitor you choose has all the ports to connect with your other gadgets and devices.

Importance of Compatibility with Existing Systems

It’s important to make sure that the industrial monitor you choose works well with your hardware setup to avoid spending extra on upgrades or replacements and ensure operations without any additional costs.

Which Mounting Options Best Suit Your Setup?

Integration and Mounting Considerations

Different ways of mounting can influence how a monitor fits into its surroundings effectively. Think about whether wall mounting, desktop stands, or personalized mounts work best for your configuration. This choice affects both comfort and how space is used.

Flexibility in Installation Locations

Optimal positioning based on workflow needs is facilitated by installation options ensuring monitors can be mounted in a variety of ways to meet operational demands.

How Does Optical Bonding Enhance Display Performance?

Benefits of Optical Bonding in Industrial Monitors

Laminating a protective glass layer directly onto the display surface, in bonding reduces glare. Improves visibility, in bright lighting conditions while also enhancing durability by safeguarding against dust and moisture.

Improving Durability and Visibility

Enhancing durability is achieved by implementing bonding, which acts as a protective shield, against environmental elements that may cause harm to the display over an extended period of time. Furthermore, the enhanced visibility guarantees that operators can easily access information, in lighting conditions.

What Level of Brightness Is Required?

Selecting Appropriate Brightness Levels for Different Environments

To make sure the text is easy to read and doesn’t strain your eyes in lighting conditions; Adjust the brightness to suit the environment. In lit places, you might need brightness to offset the light, around you.

Addressing Glare and Readability Challenges

Glare reduction technologies improve readability by reducing reflections, from sources, on the screen surface making it easier for operators to work comfortably and efficiently in environments.

In summary, choosing the display requires taking into account a variety of factors such, as size, resolution, temperature range, operation touchscreen functionality, connectivity options, ways to mount it securely advantages of optical bonding, and screen brightness levels. By assessing these aspects depending on the needs of your specific application and the surrounding conditions you can make smart choices that improve efficiency and reliability. For solutions customized to suit a range of industrial needs consider exploring the diverse selection of cutting-edge products offered by Kadi Display that are crafted to meet industry standards effectively.

Why Is Viewing Angle Important in Industrial Monitors?

Analyzing Viewing Angle Specifications

The angle from which you view a monitor plays a role, in how effectively you can see the display from different positions. Having a wide viewing angle guarantees that the image quality stays the same no matter where you’re sitting on the screen. This is especially vital in environments where several workers might need to look at the monitor from various perspectives. When you’re checking out viewing angle details in monitors it’s wise to consider those, with IPS technology because they are known for their color accuracy and broad viewing angles compared to TN or VA panels.

Ensuring Consistent Image Quality from Various Positions

Maintaining image quality, at viewing angles is crucial for keeping operations efficient and precise in settings where decisions rely heavily on visual data displayed on screens. Any decline in image clarity caused by viewing angles can result in mistakes and lower productivity levels. Industrial monitors with viewing angles guarantee that everyone can see precise information regardless of where they are positioned in relation, to the screen.

What Should You Know About Enclosure Material?

Choosing Durable Materials for Longevity

The material used for the casing of a monitor is crucial, for its durability and lifespan longevity in working environments where equipment is subjected to dust particles moisture, and physical impacts such as bumps and knocks. Therefore it is essential to choose monitors with casings crafted from materials, like steel or reinforced plastics to enhance their durability and ensure they can withstand environmental wear and tear for prolonged periods while maintaining optimal functionality.

Considering Environmental Factors in Material Selection

When selecting the materials, for your enclosure setup in an environment it is important to take into account the conditions unique to your setting like changes in temperature or exposure, to chemicals and high levels of humidity which can impact how well the monitor’s enclosure holds up over time. Choose materials that are tailored to endure these conditions without sacrificing the strength and functionality of the setup.

What Certifications Are Necessary for Compliance?

Understanding IP Rating Standards

IP (Ingress Protection ) ratings are crucial, in assessing a monitor’s resistance to dust and water entry. Knowing these guidelines is key to guaranteeing that your selected monitor fulfills the required protection standards for its designated setting. Elevated IP ratings suggest enhanced defense against particles and moisture rendering them appropriate, for demanding uses.

Evaluating IK Rating Requirements

In industries where machinery often faces strain or unexpected impacts, equipment durability is crucial for lasting performance. Minimizing potential damage, in operations.

Navigating ATEX Standards for Hazardous Areas

In industries where there may be environments, it’s important to adhere to ATEX regulations. These guidelines verify that machinery is deemed safe for operation, in zones by averting ignition sources that could trigger explosions. Make sure your industrial display complies with ATEX standards, before using it in these settings.

Considering MIL-STD-810G/F for Military Applications

Military use requires devices that can handle conditions such, as impacts and vibrations as well as changes in temperature and humidity levels. Monitors following the MIL‐STD‐810 standards are tested extensively to guarantee their dependability in challenging situations, like these.

How to Choose the Right Technology for Your Industrial Screen?

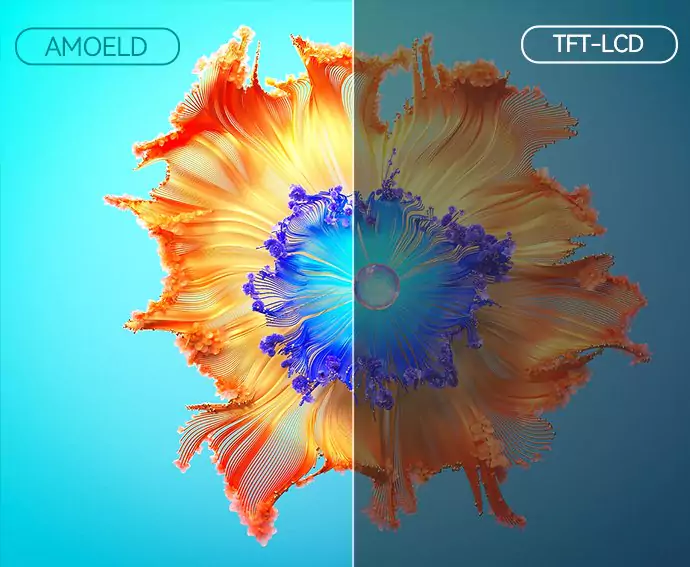

Comparing LCD, LED, OLED, and Plasma Technologies

When deciding on the display technology you’ll need to weigh your choices such, as LCD (Liquid Crystal Display) LED (Light Emitting Diode) OLED (Organic Light Emitting Diode), and Plasma screens against each other. Each type has its benefits; LCD screens are popular for being budget-friendly and energy-efficient while LEDs offer brightness ideal, for outdoor settings. OLED displays provide top-notch color accuracy. Come with a price tag and Plasma screens excel in producing sharp contrast ratios despite consuming more power compared to other options.

Which Protection Norms Should Your Industrial Monitor Have?

Assessing Protection Norms Based on Application Needs

The guidelines, for protection determine the ability of a display to endure the environmental conditions pertinent to its usage, such as exposure to dust or resilience against water infiltration, and should adhere to industry norms applicable, in your field or area.

Explore Kadi Display’s Advanced Solutions

Here, at Kadi Display we specialize in creating top-notch solutions tailored to meet the needs of industries. Our team of professionals is dedicated to delivering excellence in research and development production, sales, and service on a scale. We are well known in North America, Western Europe, and Southeast Asia for our cutting-edge products such as TFT LCD touchscreens, OCA bonding technology, driver boards, cables, and shell housing with quality assurance.

We pride ourselves on offering pricing after-sales support no minimum order quantity requirements, guaranteed long-term supply availability, a 12-month warranty period, and acceptance of small orders. Our knowledgeable staff is always on hand to assist in ensuring an integration into your existing systems and enhance efficiency, reliability, and productivity levels, for the utmost satisfaction of customers worldwide!

Latest Blog & News

- AMOLED vs LCD: Top Differences and How to Choose

- What is HMI Screen, Common Uses, Trends and the Future of HMI

- Top Manufacturers of Stretched Bar LCD Displays for Custom Solutions

- Medical Monitors: What Sets Them Apart

- Sunlight Readable Displays – the Key Parameters of Outdoor LCD Displays You Need to Know